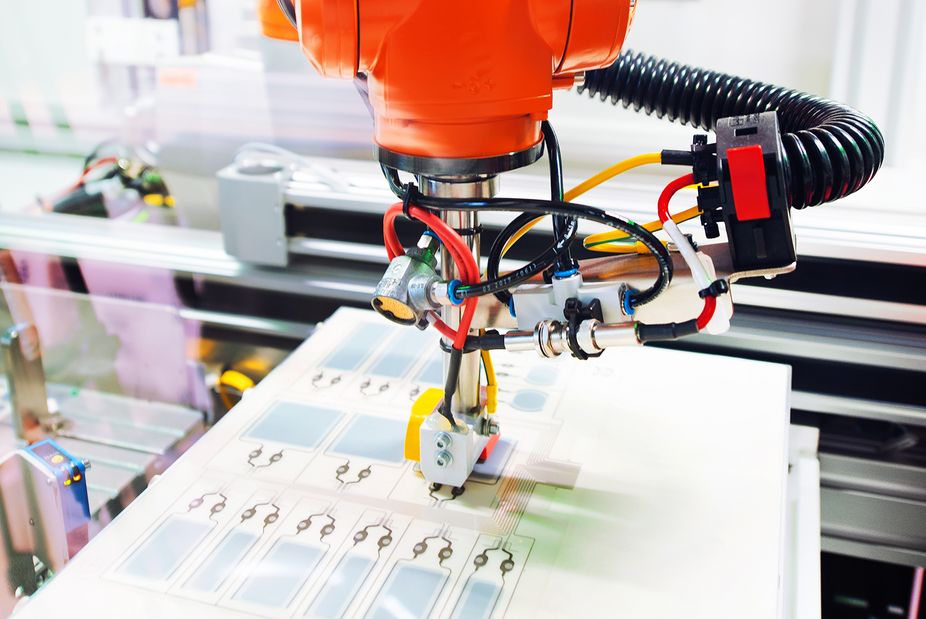

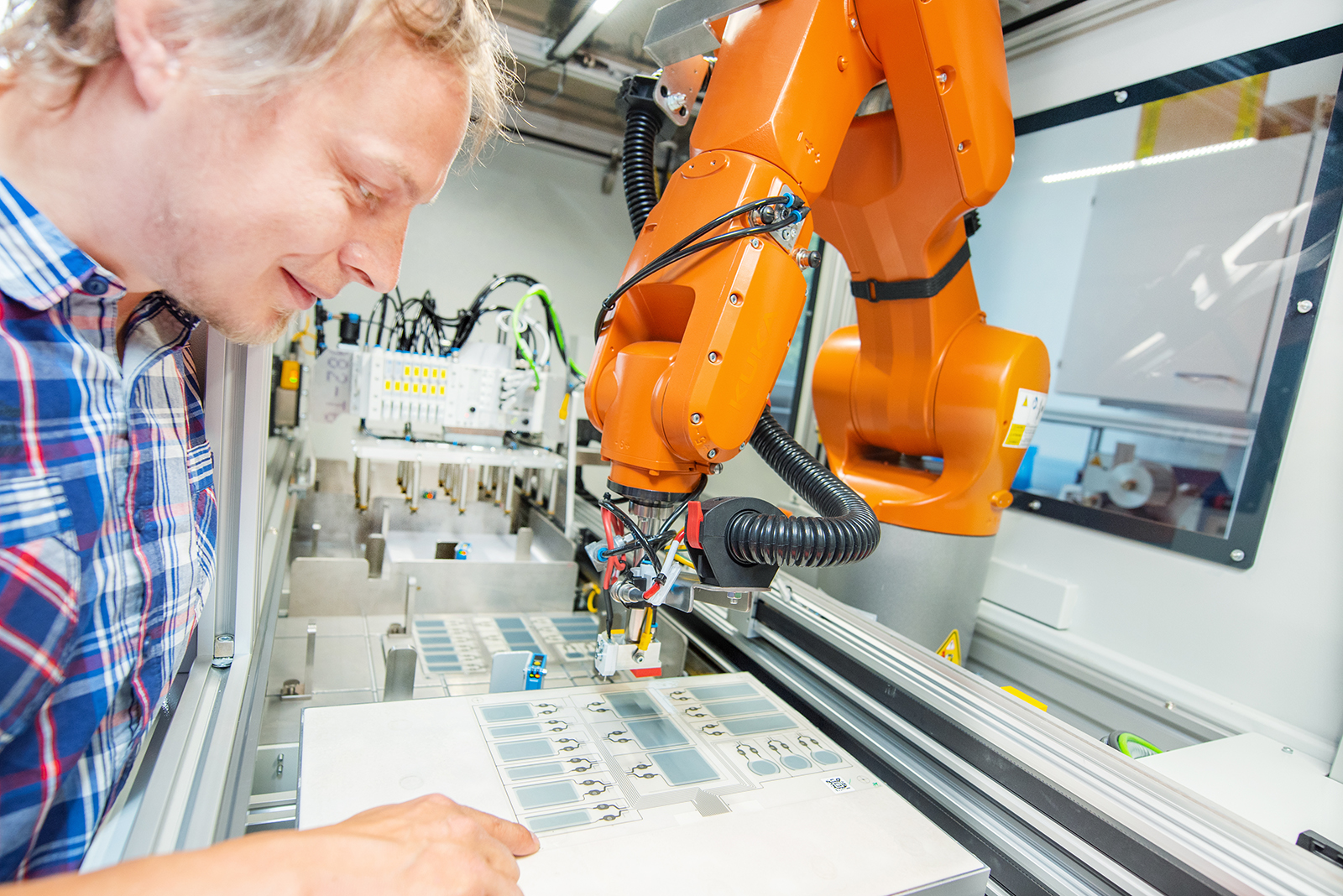

MATERIALS researchers developed new infrastructure for automated drying and poling of Pyzoflex® sensors.

Together with the Austrian company Eberle Automatische Systeme GmbH & Co KG, a team from MATERIALS, the Institute for Surface Technologies and Photonics at JOANNEUM RESEARCH, developed the globally unique poling system, which has recently gone into operation for research purposes. Project manager Martin Zirkl, a specialist in ferroelectric polymer sensors, explains the function of the new facility: "After the sensors have been applied to foil, they have to undergo a drying and poling process for heating and activation. Recent studies have shown that drying and poling have a significant influence on the properties of the sensors." The quality and thus the reliability in the application of the sensors is enormously important - for example for the safety of people working together with robots. The sensors must react very precisely to pressure so that there is no risk of injury to humans.

MATERIALS is now trying to close the gap between pressure and quality assurance of sensors with the unique and specially developed system using a completely new method.

"Our recent research on the screen printing processes used to manufacture the sensors has shown that the sensor sensitivity and quality is much more dependent than previously thought on the details of the drying and polishing processes of the sensors, which immediately follow the printing process of the sensors," Zirkl elaborates.

"With the new devices, we want to deepen and further develop the research work in the area of functionalising different surface materials for PyzoFlex® sensor technology and prepare it for new innovative applications such as condition monitoring in the industrial environment," Zirkl explains the added value for business and industry.

The infrastructure was funded by the Future Fund Styria for Research Infrastructure in the area of "non-economic use".