Research consortium from Austria and China prints heat conductors from graphene

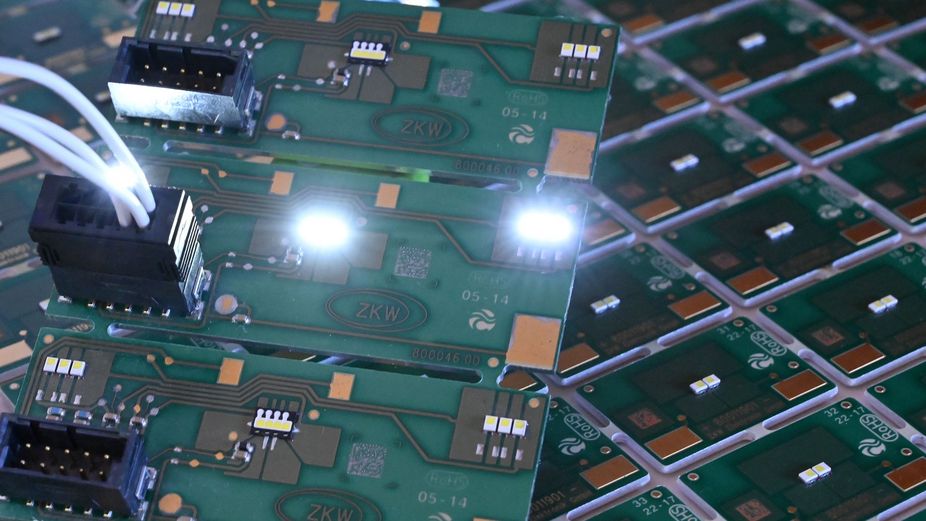

Modern light sources consist of powerful light emitting diodes (LEDs). In order to implement new functionalities such as intelligent or adaptive lighting, the number of these LEDs per area is continuously increasing in modern lighting systems. However, such highly integrated LEDs generate significant heat during operation, which must be efficiently dissipated in order to optimize the LED’s operating conditions and service life. It is therefore important to develop materials with good thermal conductivity that can efficiently dissipate the excess heat.

New material as a heat conductor

A material that conducts heat particularly well and is also inexpensive and environmentally friendly is graphene, an atomically thin layer of carbon atoms. However, it is currently still difficult to integrate graphene heat conductors at an industrial scale with LED structures. As part of a project funded by the Austrian Research Promotion Agency (FFG) and the Chinese Academy of Sciences, international partners led by JOANNEUM RESEARCH, Institute MATERIALS, have investigated a new method for integrating graphene with LED structures. The results of the study have now been published in the scientific journal ACS Omega.

Similar as in a conventional inkjet printer, layers of graphene were printed on LED components. While inkjet printing however only allows low-viscosity inks and printing on flat surfaces, so-called aerosol jet printing was used in this project. "This way, cheaper, more viscous graphene inks can also be used and controlled printing can also be carried out on rugged, rough surfaces, as often found in LED structures," explains Reinhard Kaindl from JOANNEUM RESEARCH, head of the international consortium and first author of the study.

The Austrian-Chinese consortium at a project meeting in Vienna (picture taken before the COVID pandemic), Credit: TU Wien/ Bernhard Bayer

Optimized printing process

"In order to optimize the printing process and to be able to print heat conductor structures directly onto LED components, different inks and printing conditions were compared", explains Bernhard C. Bayer from the TU Wien, responsible for materials characterization in the project and last author of the study.

"The international collaboration with the Austrian research partners JOANNEUM RESEARCH and TU Wien as well as with ZKW, a global leader for innovative premium lighting systems in the automotive sector, was very enriching for us," says Wencai Ren, world-renowned expert for graphene at the Institute of Metal Research of the Chinese Academy of Sciences who brought his leading expertise in ink development to the project.

"Through the joint project we were able to test how well graphene can function as a heat conductor in modern, intelligent headlight solutions. We achieved promising initial results," adds Dietmar Kieslinger from industrial partner ZKW Elektronik GmbH.

"The bilateral project funding and the excellent cooperation in the project team enabled us to combine the strengths of the Austrian and Chinese academic and industrial partners in a unique way," summarizes Paul Hartmann, director of the Institute MATERIALS at JOANNEUM RESEARCH.

The described work has been funded by the FFG and the Chinese Academy of Sciences as part of the GRATEC project.

Original publication

Kaindl et al., Aerosol Jet Printing of Graphene and Carbon Nanotube Patterns on Realistically Rugged Substrates, ACS Omega, ACS Omega, 6, 34301, (2021), https://doi.org/10.1021/acsomega.1c03871

Contacts

Dr. Reinhard Kaindl

JOANNEUM RESEARCH, MATERIALS-Institut für Oberflächentechnologie und Photonik

+43 316 876-3303

https://www.joanneum.at/materials

Twitter: @ReinhardKaindl

https://twitter.com/ReinhardKaindl

Dr. Bernhard C. Bayer

TU Wien, Institut für Materialchemie

+43 1 58801 165 228

bernhard.bayer-skoff@tuwien.ac.at

Twitter: @nanobayer

, from 11:00 (multi-day)

22nd Annual STS Conference Graz 2024 - Critical Issues in Science, Technology and Society Studies

TU Graz, hybrid, from 09:00 (multi-day)