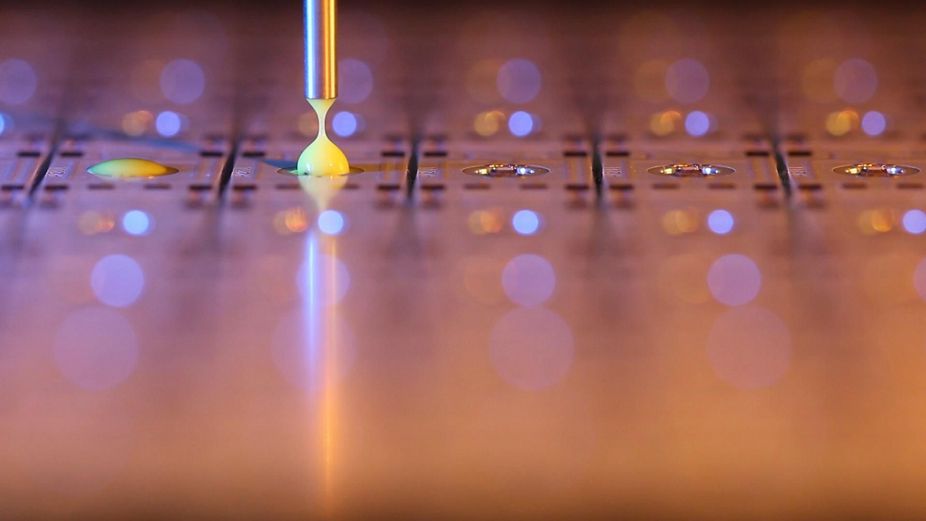

Most LED components use special silicones (PDMS) as matrix for the colour conversion phosphors, or as the favourite material for primary optical lenses attached to the LED package.

In LED production, two-component systems are used that start curing immediately after they are mixed. The mixture usually has a pot life limited to a maximum of few hours at room temperature, which leads to serious practical and technological limitations for its use.

Researchers at the JOANNEUM RESEARCH Institute MATERIALS have developed a novel method for stabilizing PDMS elastomers.