Atmospheric pressure plasma coating

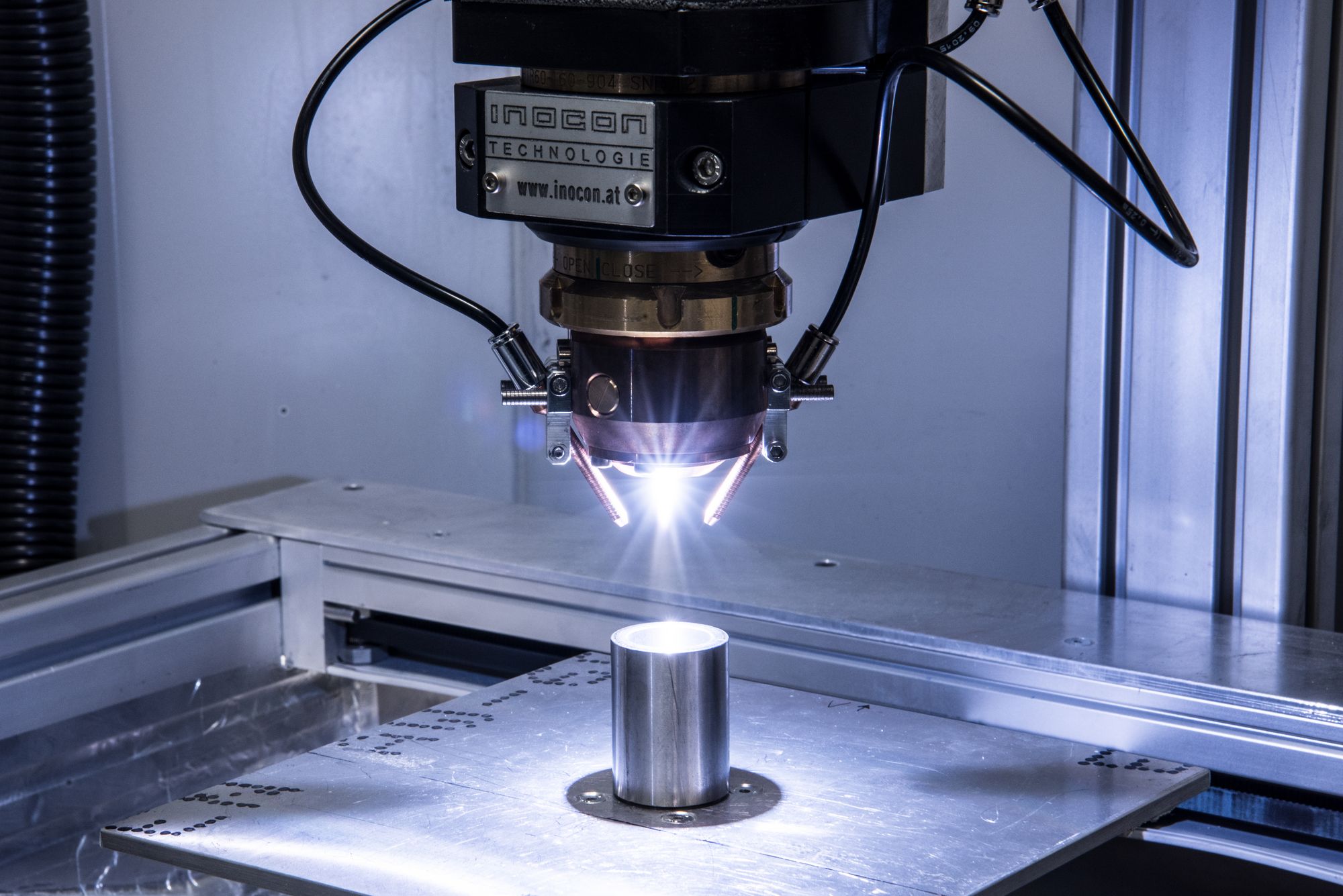

At its Niklasdorf site, MATERIALS offers its customers not only high and fine vacuum plasma coating technologies but also atmospheric pressure plasma technologies with a coating system that was installed and successfully implemented as part of a cooperation with the company INOCON Technologie GmbH.

The coating system is based on a patented hot gas plasma nozzle developed out of the Plasmatron® plasma welding technology by the project partner INOCON. The system enables to coat large substrates and promises a significant cost reduction of plasma-assisted coating processes, as the pressure in the plasma corresponds to the ambient atmospheric pressure. Thus, in contrast to low- and high-pressure plasmas, no cost-intensive reaction vessel (e.g. vacuum chamber) is required. The process is characterised by a high degree of flexibility in terms of the coating materials that can be applied. Composite coatings can be realised as well by mixing functional particles into the plasma together with the precursor gases for plasma polymerisation.

Compared to the widely used thermal spray heads, this plasma nozzle already works stably at relatively low power. This means a lower temperature load for the substrate, which allows using even temperature sensitive materials such as polymers. Thanks to the optimised electrode and nozzle shapes and the adaptable gas flows, a very large working distance (up to 120 mm vs. 30 mm) can be used with an increased plasma jet diameter (up to 55 mm vs. 20 mm) compared to the state-of-the-art technology. This clearly improves the applicability for 3D surfaces, such as touch screens, handrails and grab rails in public transport with antibacterial properties.

Currently, the atmospheric pressure plasma technology is used for the activation of polymer surfaces by oxygen or inert gas as well as the deposition of metal, oxide and polymer coatings. In the future, such coatings will be applied as wear protection, corrosion protection and barrier layers or as biocompatible, antibacterial and biofunctional layers as well as electrical insulation layers or conductor paths and electrodes.