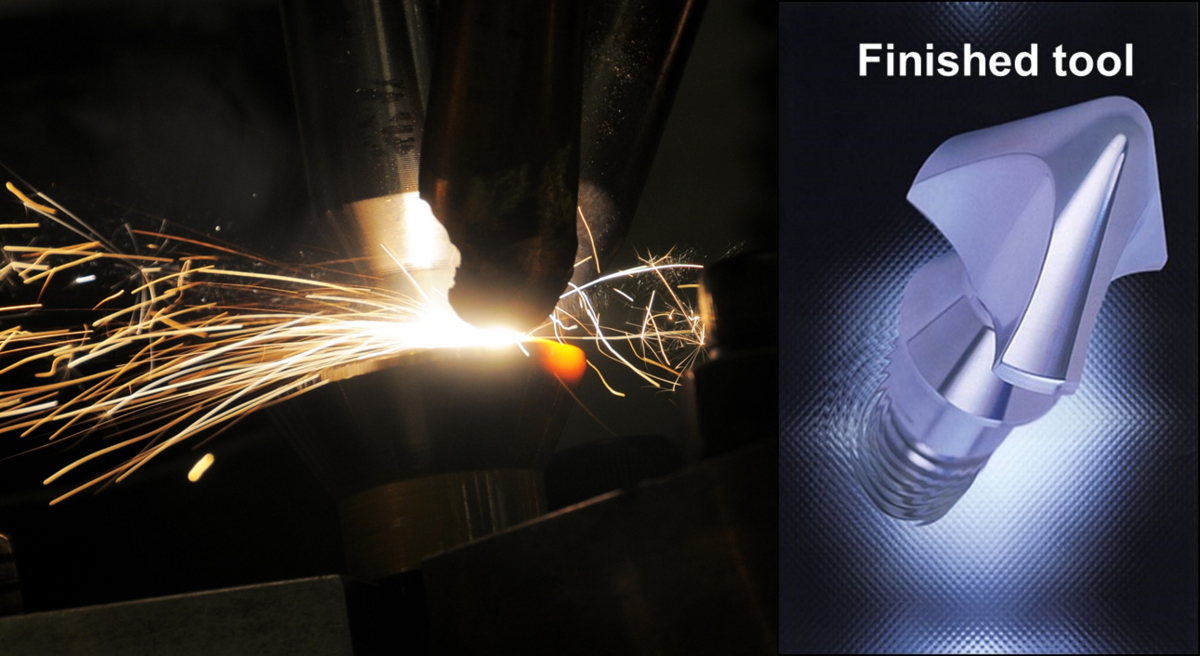

Laser alloying of a back-flow valve and finished tool (© Engel Austria GmbH)

Laser alloying

Laser alloying allows unique solutions for local material modification. The strength of laser alloying lies in the moderate modification of the chemical composition of the base material.

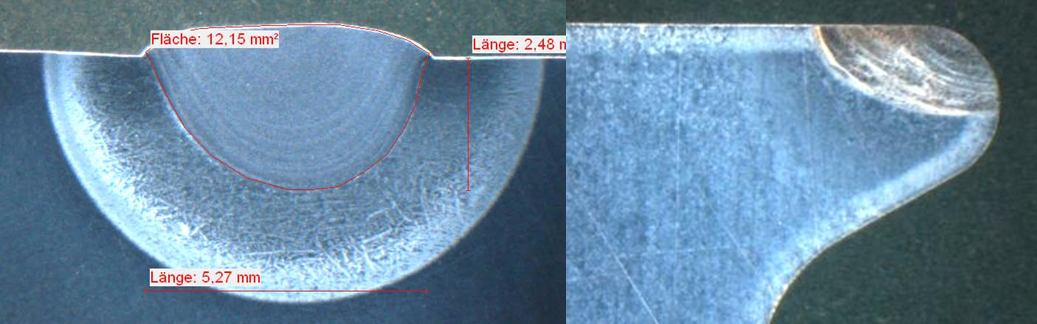

Metallographic slice through a laser-alloyed bending tool, before and after finishing

The laser beam is moved continuously along a surface, thus locally melting the base material. Into the stable melt pool additional powder material is blown. The powder particles get completely solved in the overheated weld pool and lead to a change in chemical composition. Homogenization is achieved via strong weld pool convection, which can be influenced in their flow characteristics by addition of surface-active substances. Thus, it is possible to adapt the shape of the alloyed zone to the required demands.

The required material properties can be tuned very precisely via the continuous adjustment of the dilution over a wide range. This technology enables the creation of new alloys directly on the component or tool, i.e. the fabrication of a composite material which partially allows the adjustment of different material properties of the base material.

Therefore laser alloying enables technological solutions that cannot be achieved by any other technique. Local wear protection on highly stressed tools is a typical application of laser alloying. We have developed an alloying concept that is used successfully in industrial applications.