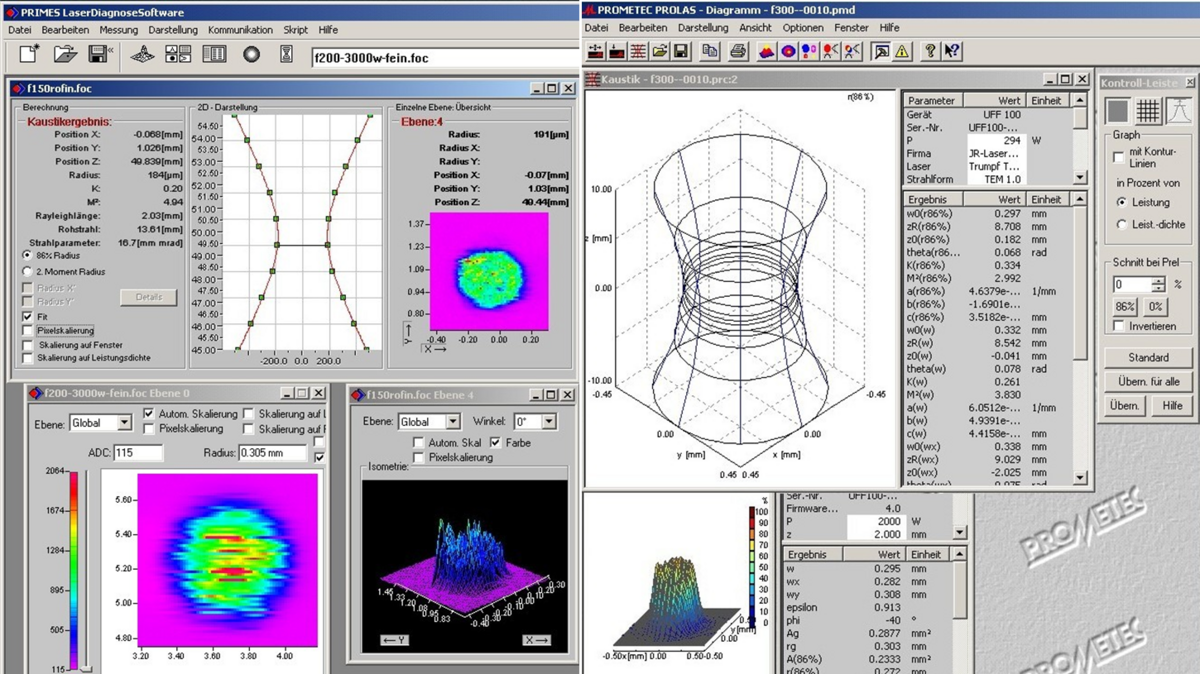

In the field of industrial production the utilization of lasers is common practice for, e.g., welding or cutting processes. Especially for sensitive processes minimal deviations in the important laser beam parameters like power, focus position, beam diameter, beam shape (caustics) or intensity distribution can be decisive for the production yield.

In modern process and quality management therefore the periodic monitoring of the laser beam is an essential task for maintaining process stability. The same is true for changing (even single components of) the optical part of the machines, since equal specifications do not rule out individual differences.

Moreover, pollution of the protective glass that are invisible during visual inspection may strongly alter product quality. The equipment for laser beam monitoring and analysis of all these process-changing beam parameters is costly. Furthermore, both the selection of the suitable measuring device and the performance of the measurements, as well as the interpretation of the results require a high degree of experience.

Based on a long-term experience in laser process development and laser beam analysis MATERIALS offers such measurements as a service.