Shaping the future, together

Our innovations enable us to drive the long-term, people-centred development of our society, the economy and industry.

About us

Jointly owned by the federal provinces of Styria, Carinthia and Burgenland, we are a non-university research company headquartered in Graz, Austria. With around 500 employees from more than 25 countries, we carry out research at six locations, developing solutions and technologies for society, the economy and industry.

Dr Heinz Mayer

Managing Director, JOANNEUM RESEARCH

Dr Heinz Mayer

Managing Director, JOANNEUM RESEARCH

Owners and management bodies

JOANNEUM RESEARCH is owned by the Federal Province of Styria, Kärntner Betriebsansied-

lungs- & Beteiligungsgesellschaft (BABEG) and Wirtschaftsagentur Burgenland GmbH. Our key management bodies are the Managing Board, the Supervisory Board and the Scientific Advisory Board.

Find out more

The Federal Province of Styria has an 80.75% interest in JOANNEUM RESEARCH.

Kärntner Betriebsansiedlungs- & Beteiligungsgesellschaft (BABEG) holds 14.25% of the shares.

As one of Austria's largest research institutes, we live up to our responsibility to identify and develop solutions for challenges facing society, including climate change, energy supply, health and care, digital transformation, mobility and social change.

Find out more

Are you looking for a reliable research partner for your project?

Contact us today – we’d be delighted to hear from you!

Locations

Global network, local roots – you can find a list of all our locations including contact details below:

JOANNEUM RESEARCH Forschungsgesellschaft mbH

Leonhardstrasse 59

8010 Graz

+43 316 876-0

info@joanneum.at

Directions via Leonhardgürtel 10

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

DIGITAL Institute

Steyrergasse 17

8010 Graz

+43 316 876-5000

digital@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationHilmwarte, Roseggerweg 31

8010 Graz

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDigital Twin Lab Klagenfurt, Lakeside B13b

9020 Klagenfurt am Wörthersee

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

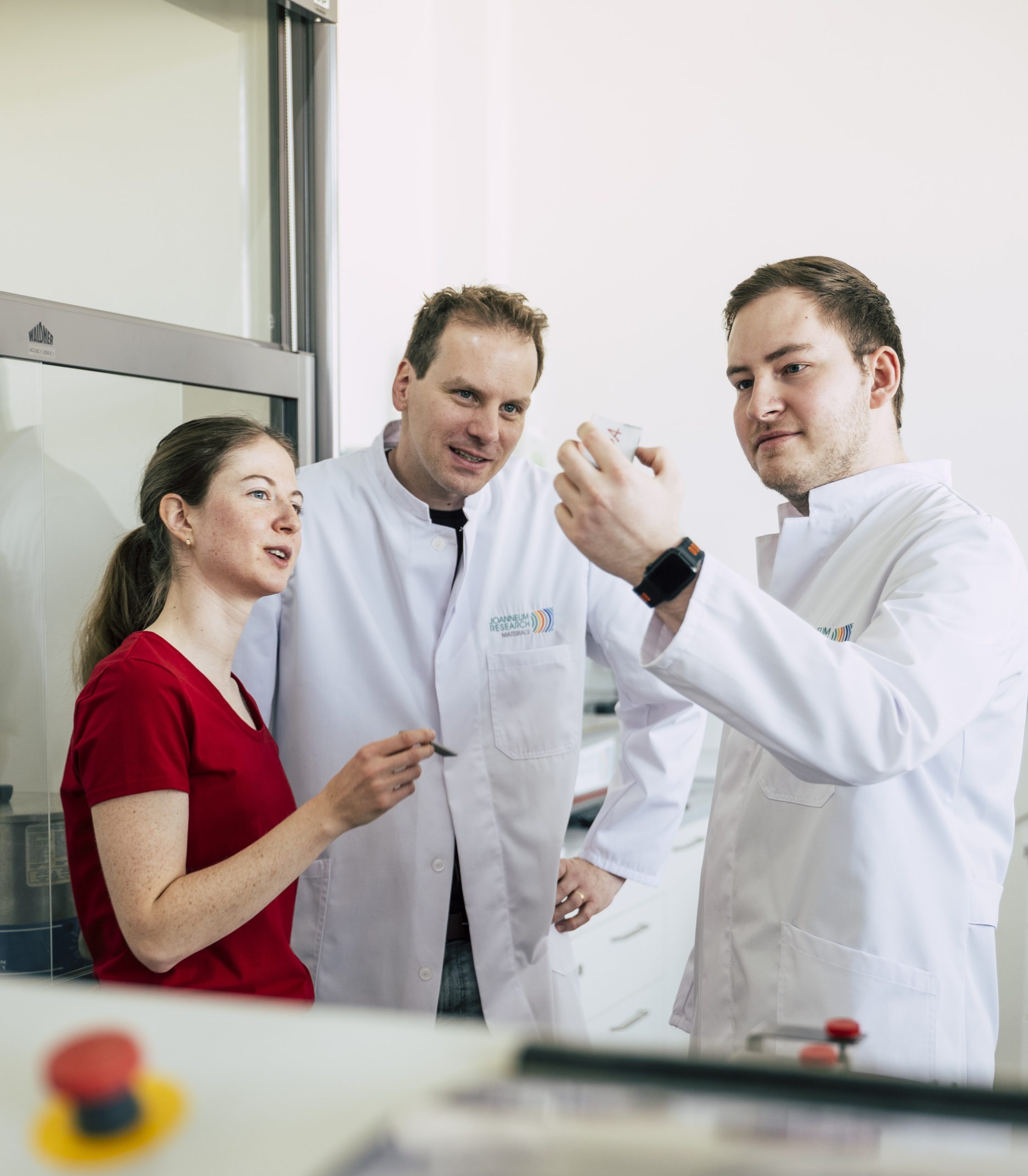

MATERIALS Institute

Franz-Pichler-Strasse 30

8160 Weiz

+43 316 876-3000

materials@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationLeobner Strasse 94a

8712 Niklasdorf

+43 316 876-3304

MATERIALSNiklasdorf-Sek@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTechnologiezentrum Pinkafeld

Industriestrasse 6

7423 Pinkafeld

+43 316 876-3600

materials-scl@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

ROBOTICS Institute

Lakeside B13b

9020 Klagenfurt am Wörthersee

+43 316 876-2000

robotics@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

COREMED Centre

Neue Stiftingtalstrasse 2

8010 Graz

+43 316 876-6000

coremed@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

HEALTH Institute

Neue Stiftingtalstrasse 2

8010 Graz

+43 316 876-4000

health@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

LIFE Institute

Science Tower, Waagner-Biro-Strasse 100

8020 Graz

+43 316 876-7600

life@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationLakeside B13b

9020, Klagenfurt am Wörthersee

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

POLICIES Institute

Leonhardstrasse 59

8010 Graz

+43 316 876-1561

policies@joanneum.at

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSensengasse 3/3/1

1090 Vienna

+43 1 581 75 20

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationLakeside B13b

9020 Klagenfurt am Wörthersee

+43 316 876-7553

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationEqual opportunities, a commitment to gender equality and respect for all cultures, with a view to creating a diverse environment where people can live and work together, are integral components of JOANNEUM RESEARCH’s strategy.

Find out more

(ESG-Reporting)

Click here to download media information, photos and videos, annual reports and logos,

as well as copies of our customer magazine JOANNOVUM.