In industry, additive manufacturing is used to produce complex ceramic components, such as rods, lattice structures, gears and impellers (rotating parts in pumps) as well as plates with fine internal structures. Of particular relevance are the kinds of applications that call for high precision and material density – for instance in sensor technology, medical engineering and microsystems technology, where even the smallest air inclusions can impair the function of the component. However, in industrial 3D printing of ceramic parts, fine defects can potentially occur during the manufacturing process – and especially those tiny air inclusions in the material. While often invisible to the naked eye, these bubbles can compromise the stability or functionality of the part in question. In the Austrian Research Agency-funded MILAM project (Production of the Future), Harald Ganster’s team at DIGITAL conducted research into how best to identify sources of error during the printing process, rather than after – using image processing, hyperspectral analysis and AI.

Early defect detection during printing

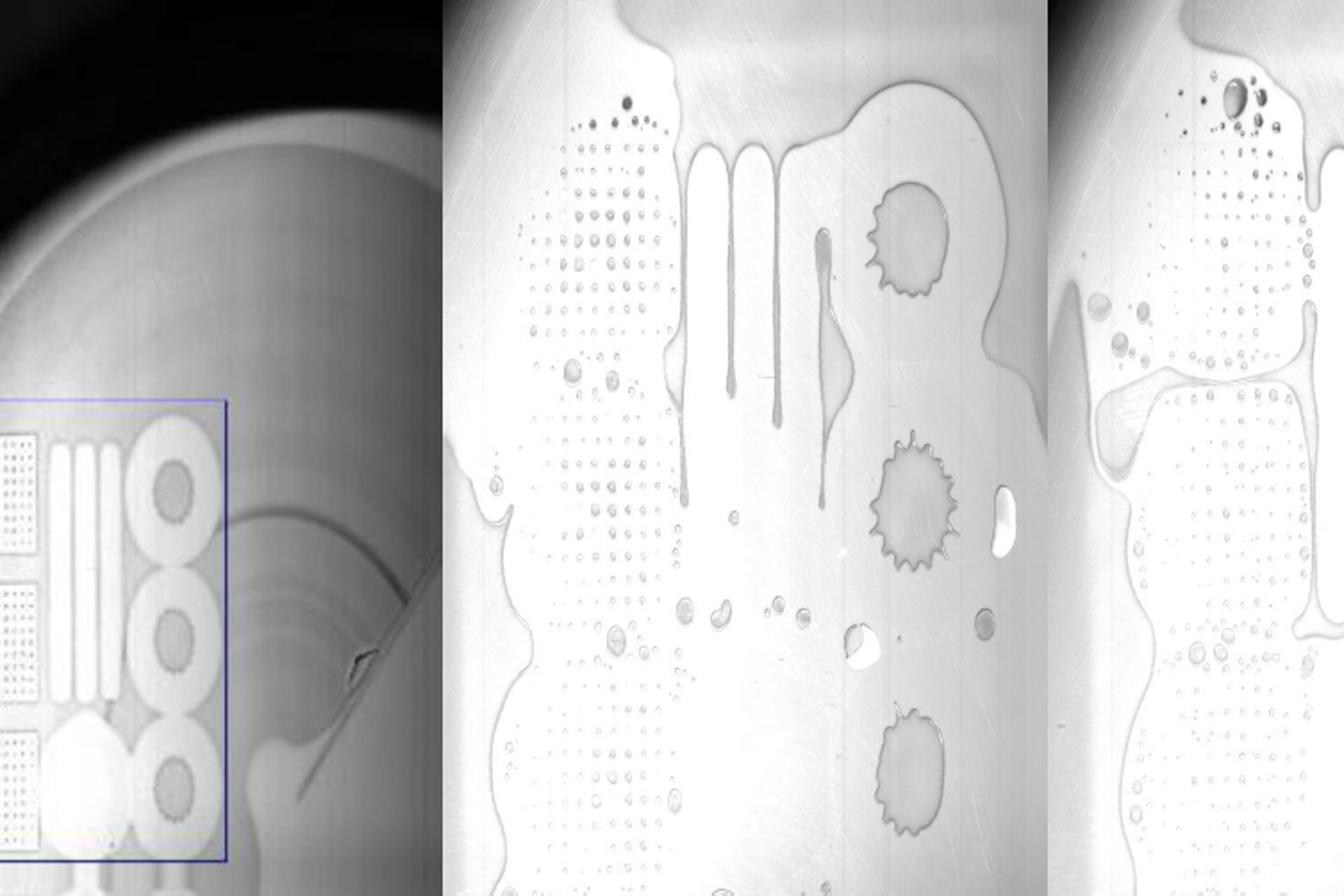

"We developed a camera-based monitoring unit that was integrated directly into a 3D printer supplied by our industry partner Lithoz GmbH. It pinpoints air bubbles as well as potential contaminants in the liquid material – what we call slurry – before each layer is cured. And because these cameras provide high-res images of every single printed layer, we have the basis for automatic analysis already in place," explains Ganster. The data they gather are not only stored but also evaluated with the help of artificial intelligence. The aim is to detect any bubbles automatically and assess whether they could potentially compromise the integrity of the component. This involves a number of modern deep learning techniques, including convolutional neural networks (CNN) and specially adapted variants such as YOLO (You Only Look Once). The AI identifies structures in the images, classifies them as potentially critical or non-critical bubbles and learns from each new dataset.

Hyperspectral analysis – material insights

In addition to image analysis with standard cameras, the project also employed something called hyperspectral analysis – a measurement technique that not only captures an image, but an entire light spectrum for each pixel. This makes it possible to determine material-specific properties such as the degree to which an individual layer has cured. "We have our own hyperspectral laboratory at our site in Graz, where these tests were carried out. In the lab, different states of the printing material could be analysed and optically distinguished from one another. Initial results show that cured and uncured areas can be clearly differentiated – although there are still challenges at transitions between different degrees of hardness. So hyperspectral analysis provides valuable additional information for process monitoring,” Ganster explains.

AI superpower

The use of AI for automatic detection and classification of air bubbles proved particularly successful in the project. To achieve this, large quantities of image data were collected and then labelled manually (annotated) before being used to train neural networks. "Using AI not only allows us to detect air bubbles, but also lets us analyse their shape, size, contrast and position," says Ganster. Defects, such as larger inclusions inside the component, can be identified automatically using this approach. The occurrence of bubble clusters – multiple inclusions in one spot – can also be detected. Ganster: "One major technical advance came through aligning the camera images with the print plan so that we could clearly distinguish whether a bubble was actually inside the part or outside it. This is crucial, as it avoids false alarms that cause costs and delays."

From the lab to real-world use

The use of AI for automatic detection and classification of air bubbles proved particularly successful in the project. To achieve this, large quantities of image data were collected and then labelled manually (annotated) before being used to train neural networks. "Using AI not only allows us to detect air bubbles, but also lets us analyse their shape, size, contrast and position," says Ganster. Defects, such as larger inclusions inside the component, can be identified automatically using this approach. The occurrence of bubble clusters – multiple inclusions in one spot – can also be detected. Ganster: "One major technical advance came through aligning the camera images with the print plan so that we could clearly distinguish whether a bubble was actually inside the part or outside it. This is crucial, as it avoids false alarms that cause costs and delays."

by Elke Zenz