At the heart of KRAISBAU is the question of how existing buildings can be reused as effectively as possible – through conversion, refurbishment and intelligent renovation or resources. Using the example of a vacant school building in Salzburg, which is to be used as an innovation location in the future, new methods for the industry are being tested in practice. A research team from DIGITAL, the Institute for Digital Technologies at JOANNEUM RESEARCH, is conducting comprehensive surveys of the building using visual sensor technology (3D measurements, hyperspectral sensor technology), thus providing a basis for decisions on potential uses.

Reallabor Salzburg: Innovation trifft Bestand

Die ehemalige Josef-Rehrl-Schule in Salzburg wird von „Innovation Salzburg“ als Demoprojekt in KRAISBAU eingebracht. Das landeseigene Gebäude soll durch Sanierung und Zubau zu einem multifunktionalen Innovationsstandort entwickelt werden. Während der Planungsphase dient es als Reallabor für zirkuläres Bauen. „Wir wollen das Gebäude künftig für unsere Organisation und als Ort für Start-ups, Makerspaces und MINT-Förderung nutzen – und dabei testen, wie sich ein Bestandsbau nachhaltig und flexibel weiterentwickeln lässt“, erklären Werner Balika und Markus Graggaber von der Innovation Salzburg. „Gemeinsam mit Partnern wie der JOANNEUM RESEARCH setzen wir auf Digitalisierung und Sensorik, um tragfähige Konzepte für die Bauwende zu entwickeln.“

Tragbare Laserscanner und intelligente Bildanalyse

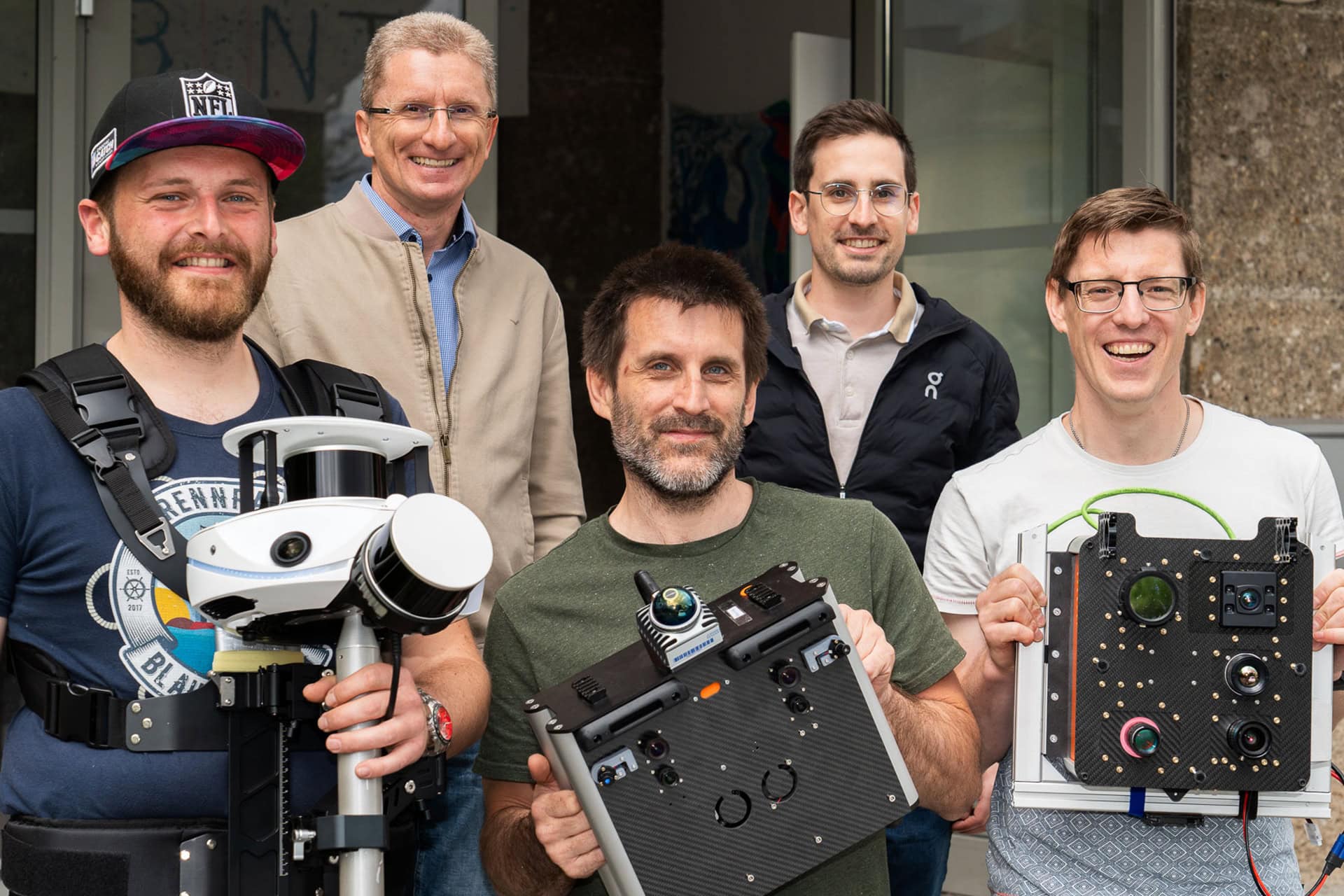

Georg Thallinger, Projektleiter von JOANNEUM RESEARCH, erklärt die Vorgehensweise bei der Bestandsaufnahme: ‘We use two different portable 3D scanners to capture the entire building, from the basement to the roof, under real conditions. The process enables the creation of point clouds and digital building models, i.e. 3D models. This allows us to test two systems in the project: a commercial, cost-intensive one and an economical one that we developed ourselves.’JR researcher Gerald Lodron tested the economical version on site: ‘This mobile system with multiple cameras and LiDAR, which we designed and built, works with inexpensive sensor technology and achieves a high measurement accuracy in the range of one to two centimetres. This enables us to automatically record materials and draw conclusions about their reusability and renovation potential. However, the point clouds and further evaluations are only created after the recording.’

One challenge for this system is to logically link and display the 60 rooms.

Werner Pretscher hat das Gebäude mit einem kostspieligen mobilen 3D-Scanner aus dem Digital Twin Lab der JOANNEUM RESEARCH erfasst. Dieses wird wie eine Steadycam getragen. Die Technologie liefert präzise Daten in Echtzeit und ist besonders geeignet für Bestandsbauten, wie die Josef-Rehrl-Schule, ohne aktuelle Pläne, etwa vor Sanierungen oder Umbauten.

Werner Pretscher calls it a ‘reality check’: ‘With our portable laser scanner, we can quickly and accurately capture existing buildings, even if no current plans exist. The point cloud generated forms the basis for digital twins, construction plans, CAD models and even energy performance certificates. And it is processed locally.’

In addition, camera systems are used to analyse visible and invisible characteristics of building materials. This combination of colour, infrared and thermal imaging cameras makes it possible to visualise moisture distribution or pipe routes, for example, without having to destroy anything. Machine vision expert Malte Jaschik's images provide detailed insights into the building fabric of the old building. With the help of artificial intelligence, this data is then automatically interpreted in the next step – for example, to identify types of building materials, electrical installations or damaged areas.

Malte Jaschik ‘This setup allows us to determine whether the inventory can be used as is, or whether parts can be dismantled and recycled.’

Research with direct relevance to construction practice The JOANNEUM RESEARCH team is contributing its expertise in the fields of image processing, sensor technology and recycling technology to the project, using innovative AI methods. In close cooperation with its partners, AI-based methods are being developed that can be used to automatically identify reusable components and analyse construction waste.

One of KRAISBAU's key objectives is to transfer the knowledge gained into practice: fact sheets, training courses and digital tools will be used to make the project results available to as many stakeholders in the construction industry as possible. For more information and partners, visit: www.kraisbau.at