- About us

- Research fields

- DIGITAL – Institute for Digital Technologies

- MATERIALS – Institute for Sensorics, Photonics and Production Technologies

- ROBOTICS – Institute for Robotics and Flexible Production

- COREMED – Centre for Regenerative Medicine and Precision Medicine

- HEALTH – Institute for Biomedical Research and Technologies

- LIFE – Institute for Climate, Energy Systems and Society

- POLICIES – Institute for Economic, Social and Innovation Research

- Business areas

- Products and services

- Research infrastructure

- Participating interests

- Career

- News & events

- Publications

- Contact us

Manufacturing processes and automation

In robotics, automation processes are monitored to ensure safety when working with robots. Credit: JOANNEUM R ESEARCH/Bergmann

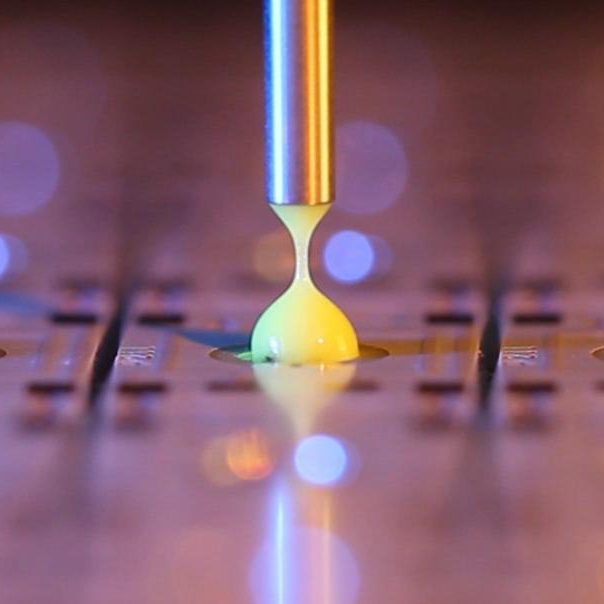

- Materials and components for micro- and nanostructuring (NILcure®)

- Optimisation of the production process for silicones (Supresil®)

- Conductive materials: Smart@Surface and CircEl-Paper

- Alloys for laser processes

- Functional component coatings

We specialise in laser welding, alloying, and cladding, focusing on material expertise, from process development to series production, including quality assurance. Additionally we have unique laser lithography methods for high resolution 3D structuring (micro- and nanometer scale) and ultra short pulse lasers.

We operate a pilot line for the production of micro and nano structures on large area polymer foils: We use Step&Repeat UV-NIL to replicate small master structures over large areas, generated with Laser lithography expertise. Our R2R-UV-Nano Imprint Lithography line enables continuous, cost-effective production of micro- and nanostructures on flexible film substrates for diverse applications such as lighting, photovoltaics, AR/VR, microfluidics, diagnos- tics, security, film finishing and packaging, pharmaceuticals, and life sciences.

In Printed Electronics, we pioneer scalable digital printing processes, including 3D printing of electronics, for producing functional components, including hybrid integration of classic components. Additionally, in 3D printing of metals and polymers , we create lighter components with comparable physical properties to conventionally manufactured ones.

We are investigating how modalities (speech, gaze, gestures, touch and mixed realities) can be used for interaction with machines. Concepts and implemen- tations can include collaborative robotics, ultrathin touch sensors, vision and acoustic systems, or AI.

Creating and using digital twins of manufacturing processes is crucial for designing, optimising and monitoring of industrial production. In process simulation, we use finite element methods (FEM) and physical modelling to simulate physical systems.

We offer support and expertise in the implementation of technologies and con- cepts for the formal verification and runtime monitoring of robotics applications.

Production and manufacturing – products and services

Umwelt-, bioanalytische und diagnostische Sensorik kombiniert mit smarten mikrofluidischen Lab-on-a-Chip und Organ-on-a-Chip-Systemen

Practical testing of automation concepts in the ROBOTICS Solution Center.

Wiederverwendbare Materialien, Komponenten bzw. Verbundstoffe und deren Anwendungen, wie z.B. selbst entwickelte Lacke für die UV-Imprint-Lithografie (NILcure®)

Laserschweißen, Laserlegieren und Laserauftragsschweißen, mit besonderem Schwerpunkt auf Werkstoffkompetenz

Projekte aus dem Geschäftsfeld Production and manufacturing

Your contact

Shaping the future, together

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.

CONTACT

JOANNEUM RESEARCH

Forschungsgesellschaft mbH

You are currently viewing a placeholder content from Accessibility Widget. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information