- About us

- Research expertise

- DIGITAL – Institute for Digital Technologies

- MATERIALS – Institute for Sensorics, Photonics and Production Technologies

- ROBOTICS – Institute for Robotics and Flexible Production

- COREMED – Centre for Regenerative Medicine and Precision Medicine

- HEALTH – Institute for Biomedical Research and Technologies

- LIFE – Institute for Climate, Energy Systems and Society

- POLICIES – Institute for Economic, Social and Innovation Research

- Business areas

- Products and services

- Research infrastructure

- Participating interests

- Career

- News & events

- Publications

- Contact us

Circular economy and sustainable use of resources

Our algorithms for establishing forest parameters at different scale levels are used for forest inventories and the transition to sustainable and climate-adapted forestry. We support the implementation of biodiversity strategies through biodiversity monitoring using a mix of satellite images, field data and citizen science.

Capture and analysis of material properties using hyperspectral analysis and machine learning to provide high quality raw materials for sustainable production. Characterisation is carried out at all stages of the recycling chain, but also as an input control to ensure the required raw material quality for production.

A specific example of life cycle analysis (LCA) for batteries in use is the Battery LifeCycle Check, which we use to analyse more climate-friendly e-mobility offerings and transport systems for companies in the automotive sector, with a special focus on battery development, production, use and, above all, recycling.

To support the electronics industry’s efforts to develop environmentally friendly and recyclable electronic-based systems (EBS), we are conducting research into lessening the environmental impact and improving recyclability of future EBS using our life cycle assessment (LCA).

When it comes to the development of new production technologies, products and forms of utilisation, we offer detailed technological and ecological (e.g. life cycle-based sustainability assessment (LCA)) as well as socio-economic assessments (e.g. macroeconomic models) for decisions on strategic direction in the interest of promoting the best technology choice for society.

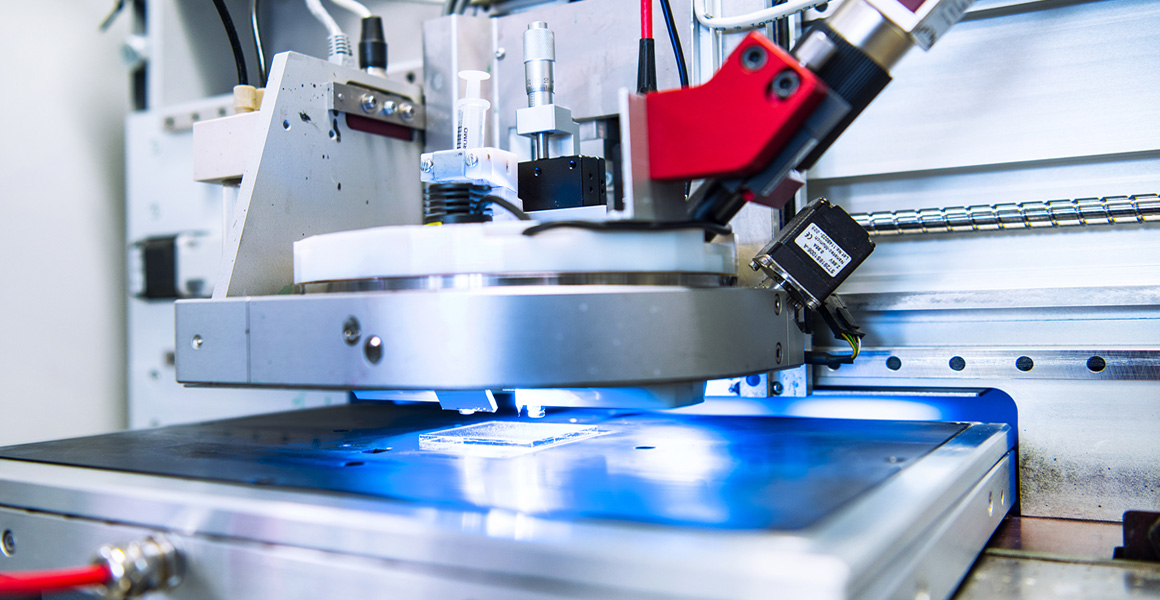

We develop scalable and digital printing processes (including 3D printing of electronics) for the generative production of functional components. We cover every stage of the process chain: material development, substrate pre-treatment, optimisation of the printing strategy, post-treatment, characterisation through to hybrid integration of classic components.

The portfolio of photopolymers includes coatings that have been developed in-house for UV imprint lithography (NILcure®). The photoresists in the product line are tailored to customer-specific applications in terms of their mechanical, chemical and optical properties for various substrates.

We conduct research into reusable materials, components and composites and their applications. Our specific focus is on high-resolution functional microstructuring and nanostructuring of sustainable polymer films and paper using bio -based resins.

We develop innovative components that are significantly lighter but still exhibit the same good physical properties as conventionally manufactured components. This is made possible though additive manufacturing thanks to newly available design and simulation tools, as well as new materials and the implementation of special lattice structures.

To increase efficiency and help reduce costs, sensors are used to monitor, measure and inspect agricultural production or are used in food inspection: optochemical sensor technology, analytical lab-on-a-chip systems and smart connected horticultural lighting.

Using modern sensor technology allows us to record specific machine data and select relevant parameters. This enables us to analyse machine performance and system status. Comprehensive sensor data also helps to integrate sustainable solutions into next-generation product development.

During the design phase, we use simulations to make sure that robot applications are optimally integrated into flexible production processes and that production resources are optimally utilised. The solutions that we propose are designed to maximise efficiency and facilitate adaptability in the highly dynamic landscape of modern production systems.

Environment and sustainability – products and services

Environmental assessment of batteries from the extraction of (critical) raw materials to recycling

Projekte aus dem Geschäftsfeld Environment and sustainability

Your contact!

Shaping the future, together

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.