- About us

- Research expertise

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Research infrastructure

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

DIVIDER: Dividing and Allocating Current Flow for Predicitve Maintenance

Duration:

10/2022

—

12/2023

Total Time:

1 Year

Predictive maintenance for automated systems and processes, Photo: JOANNEUM RESEARCH

The Project

How can maintenance be identified at an early stage?

Maintenance is often carried out according to an interval schedule or predicted proactively through monitoring of various parameters. This monitoring requires the deployment of numerous sensors and measuring devices to detect wear and sudden damages at an early stage. DIVIDER aims to determine whether it is technically possible to identify those anomalies solely through measurements and characterization of the main power supply.

Our activities within the project

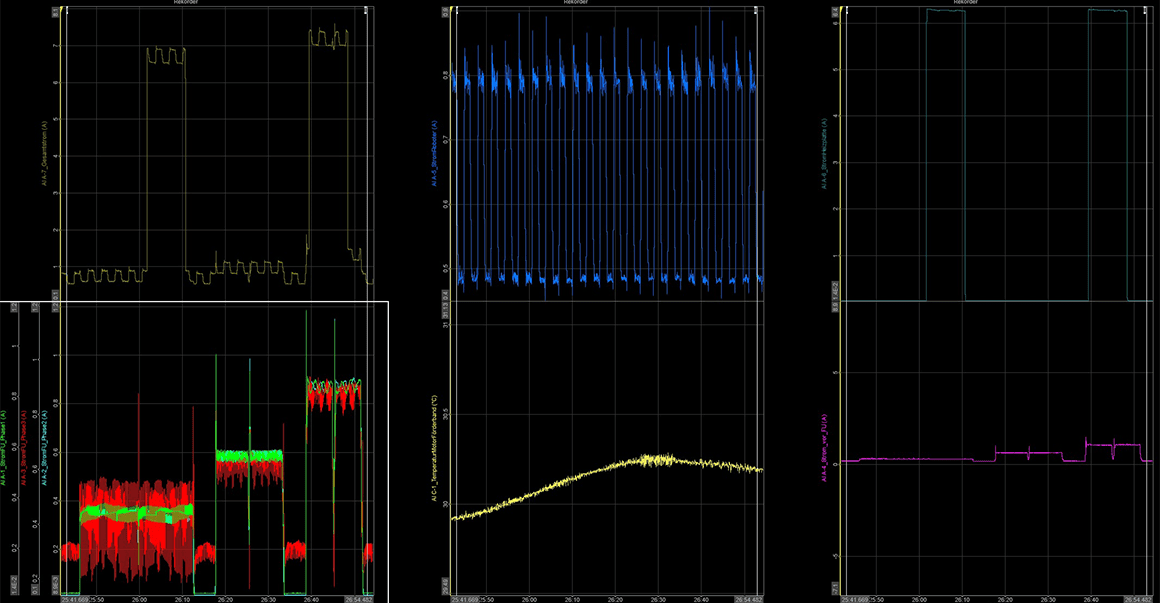

We develop mathematical models of systems with the aim of modelling the entirety of the individual system components. At the ROBOTICS Solution Centre, we commission these systems and apply forces to them to simulate wear or anomalies while measuring the main power supply in high resolution. Subsequently, we highlight these measurement data and make them accessible to machine learning. Afterwards, we validate these models ROBOTICS Solution Center.

Research group

Downloads

Sponsors

FFG

Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie (BMK)

Project Partners

Fraunhofer Austria

Messfeld GmbH

Project Details

The project DIVIDER is about the continuous monitoring of machines and systems to detect potential maintenance needs at an early stage. Normally, this monitoring requires the use of many sensors and measuring devices to identify wear or sudden anomalies. For electric machines, both electrical and mechanical measurement techniques are employed to monitor their condition.

The exploratory project DIVIDER aims to determine whether it is fundamentally possible to identify wear or spontaneously occurring anomalies based solely on measurements of the main power supply. We are using a high-precision sensor system to record the smallest fluctuations in the main power supply and store them as data points. The large datasets are then analysed, characterised and assigned using AI methods.

Projektbeteiligte

Similar Projects

SHAPING THE FUTURE

TOGETHER

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.

CONTACT

JOANNEUM RESEARCH

FORSCHUNGSGESELLSCHAFT MBH

TOGETHER | Alle Rechte vorbehalten. Created by idlab media GmbH & Lorem Ipsum web.solutions GmbH