- About us

- Research expertise

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Research infrastructure

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

FlexBotNDT: Efficient and Precise Quality Control of Materials with Collaborative Robots

Duration:

01/2022

—

12/2022

Total Time:

1 Year

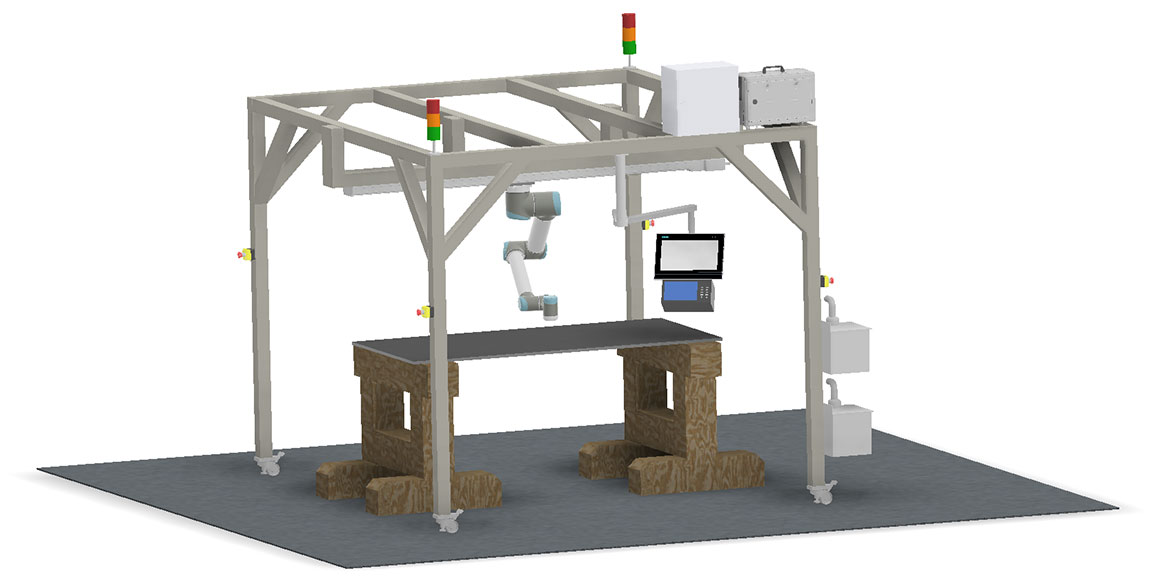

Overhead mounted robotic arm for quality control, Photo: JOANNEUM RESEARCH/Torkar

The Project

How do robots support quality control in production?

The result of the project FlexBotNDT simplifies quality control in production. Instead of performing repetitive and monotonous tasks manually, testing devices and collaborative robots (cobots) are used. These enable flexible, non-destructive material testing in which sheet metal and semi-finished products are inspected for irregularities. This approach allows more efficient and accurate quality control of semi-finished products of different sizes.

Our activities within the project

For this project, we are developing an automated testing system consisting of a specially designed end effector for applying various ultrasonic probes and a coupling medium. The movement of the end effector is controlled by a collaborative robot mounted on a linear axis.

Research group

Downloads

Sponsors

EIT Manufacturing

Project Partners

OndoSense

Voestalpine

Awesome Technologies

Laboratory for Manufacturing Systems and Automation

EIT Manufacturing

Project Details

The aim of FlexBotNDT is to develop a robotic system consisting of testing devices and collaborative robots that can be used for the quality control of sheet metal and other semi-finished products. This involves flexible, non-destructive material testing (NDT) using collaborative robots that inspect the material for cavities and other anomalies.

As part of the project, an automated testing system was created. This system comprises a specially designed end effector for attaching various ultrasonic probes and applying a coupling medium. The movement of the end effector is controlled by a collaborative robot mounted on a linear axis. This automated testing system enables non-destructive material testing of semi-finished products of various sizes.

Quality controls are a crucial step in producing flawless end products. However, these controls often involve repetitive and monotonous tasks. Employees are relieved by automating these monotonous tasks.

Sponsor

Projektbeteiligte

Similar Projects

SHAPING THE FUTURE

TOGETHER

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.

CONTACT

JOANNEUM RESEARCH

FORSCHUNGSGESELLSCHAFT MBH

TOGETHER | Alle Rechte vorbehalten. Created by idlab media GmbH & Lorem Ipsum web.solutions GmbH