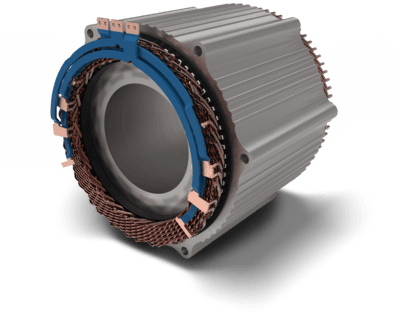

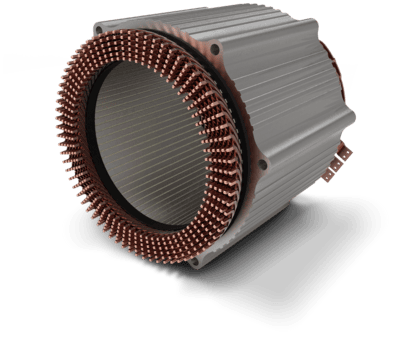

The stator is the centrepiece of every electric motor. Project partner Miba Automation Systems, which is working on setting up a production line for electric motors, is developing a process for the series production of hairpin stators as part of the FFG project IMPROFE. Hairpin technology is still relatively new in the automotive industry and enables an increase in motor efficiency on the one hand and flexible and comparatively cost-effective production, even in large series, on the other. "However, this requires certain critical characteristics of the stators to be tested inline - i.e. directly in the production process - as completely as possible," says Ulrike Kleb from the Institute POLICIES, who comes into play at this point with her team. "The mechanical positioning and interconnection of the hairpins to form an electrically conductive winding takes place in three production steps: expanding, twisting and contacting, i.e. connecting the ends with a welding spot." In the first two steps, optical measuring methods are used to collect data that provides information about the position of the pins and therefore about the quality. Quality control of the spot welds is carried out by another project partner - the Institute of Physics at the University of Graz. A laser ultrasound measurement method is used here, which makes it possible to measure directly on the weld seam. The statistical experts can then use the measurement results to make predictions for the next steps.

Digital image enables control and steering

"Ultimately, the aim is to change the machine parameters in the next production step in the event of a deviation so that the error can be prevented," says Kleb. A digital image of the stator manufacturing process is created for optimisation purposes. "This means that the manufacturing process can be better monitored and optimally controlled," explains Kleb. "Ultimately, the aim is to enable the automotive industry to produce very large quantities of high-quality hairpin stators while conserving resources." The IMPROFE research project will run until 2024.

Ulrike Kleb studied Technical Mathematics at Graz University of Technology and has been working at JOANNEUM RESEARCH since 1992. She deals with the use of data analysis, statistics and artificial intelligence for quality and resource optimisation in production.

> Project partner: Miba Automation Systems