- About us

- Research expertise

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Forschungsinfrastruktur

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

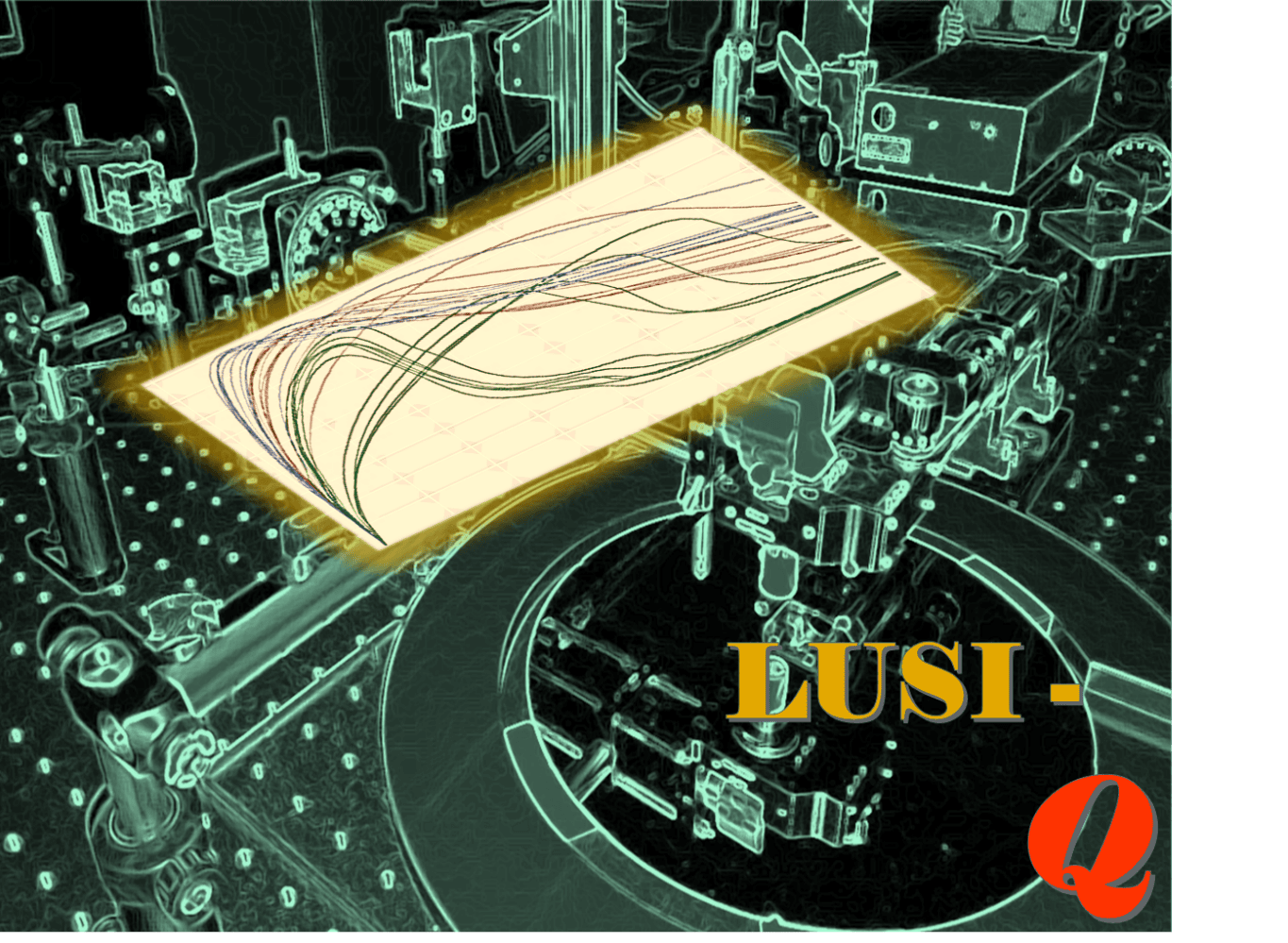

LUSI-Q Laser Ultrasound for in-line quality control in semiconductor industry

Duration:

05/2020

—

09/2023

Total project duration:

3 years

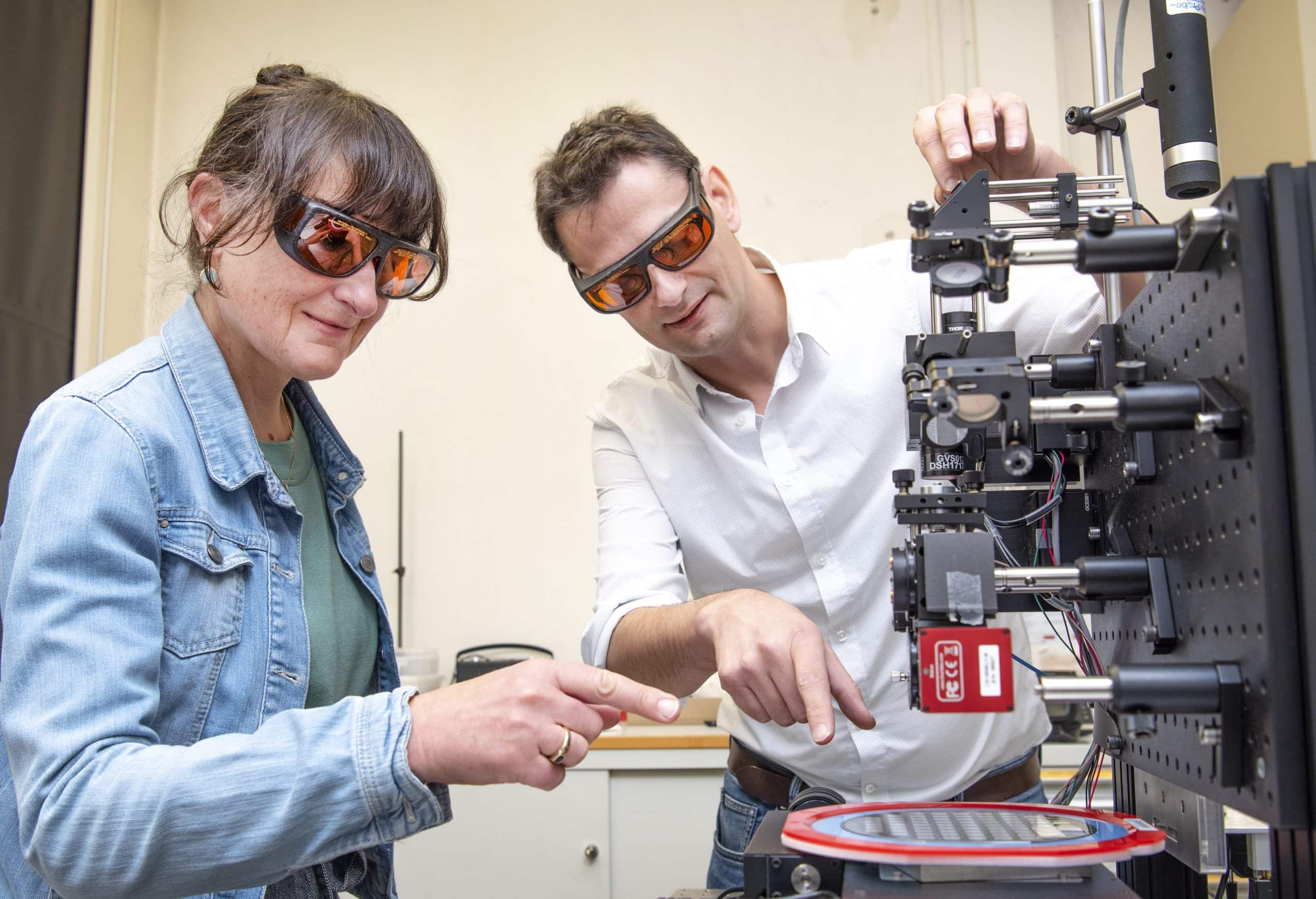

Photo: JOANNEUM RESEARCH/Schwarzl

The project

How do you detect defects in a production line?

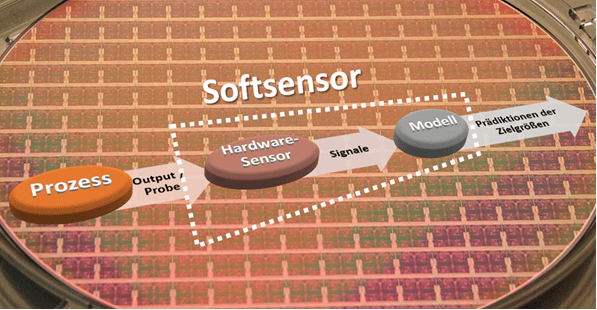

Hidden defects in chips are challenging. They can have a major impact on further production steps or consumers. Anomalies in the resulting product are rarely detected, even with intensive monitoring. In LUSI-Q, we are researching and testing a soft sensor technology for the contactless detection of anomalies in chips on wafers, based on laser ultrasound (LUS) and statistical modeling.

Our activities in the project

Laser ultrasound technology is suitable for testing components with non-contact in-line sensors: this provides characteristic signals which, when analyzed and interpreted appropriately, allow conclusions to be drawn about existing anomalies, including those inside the chip. We analyze the complex LUS signals using new methods of signal processing and innovative prediction models, such as functional data analysis (FDA).

Research groups

Downloads

Contracting Authority

FFG Produktion der Zukunft

Project partners

Universität Graz, Institut für Physik

Infineon Technologies Austria AG

MONTFORT Laser GmbH

Details of the project

High quality requirements in the semiconductor industry demand stable processes and sophisticated control concepts for quality assurance. Despite the use of different test methods, there are defects that are difficult to detect or can only be found using methods that are not suitable for in-line monitoring. For example, it is almost impossible to detect the beginnings of layer detachment on chips or defects on the chip sidewall. In addition, the detection of latent defects (such as microcracks), which only become apparent during operation at the customer's premises, is a major challenge.

Undetected defects have a negative impact on the rest of the production and supply chain:

- The further processing of defective chips ties up or wastes the resources of subsequent process steps (e .g. when installing chips in the housing) and causes costs there due to yield losses.

- If weakened components are delivered to customers, the service life of the products may be reduced.

It is therefore of great interest to the industry to avoid such cases and to ensure quality through effective and cost-effective control procedures.

Such a measuring method should be highly effective, stable and cost-effective and enable a high throughput. One promising method to meet these requirements is laser ultrasound technology.

The LUSI-Q project was researching and testing a soft sensor technology for the non-contact, non-destructive detection of mechanical anomalies in chips based on laser ultrasound (LUS) and statistical modeling for signal interpretation.

The soft sensor technology was researched using sample and defect data from the semiconductor industry and validated on two representative use cases at Infineon Villach. The project gave insights into the types and extent of hidden defects in chips that can be detected with the developed soft sensor technology and provided information on the performance of defect detection.

The project was funded by the BMK and carried out as part of the "Production of the Future" program.

Project participants

Similar Projects

Miteinander zukunftsrelevant

Die JOANNEUM RESEARCH ist Innovations- und Technologieanbieter im Bereich der angewandten Forschung. Als Forschungsgesellschaft der Länder und Regionen prägen wir mit unseren Forschungskompetenzen die Entwicklung unserer modernen Gesellschaft und Wirtschaft nachhaltig und menschenzentriert. Als multidisziplinäres Team in flexiblen, innovationsfreundlichen Strukturen leben wir höchste gesellschaftliche und wissenschaftliche Ansprüche.