- About us

- Research expertise

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Forschungsinfrastruktur

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

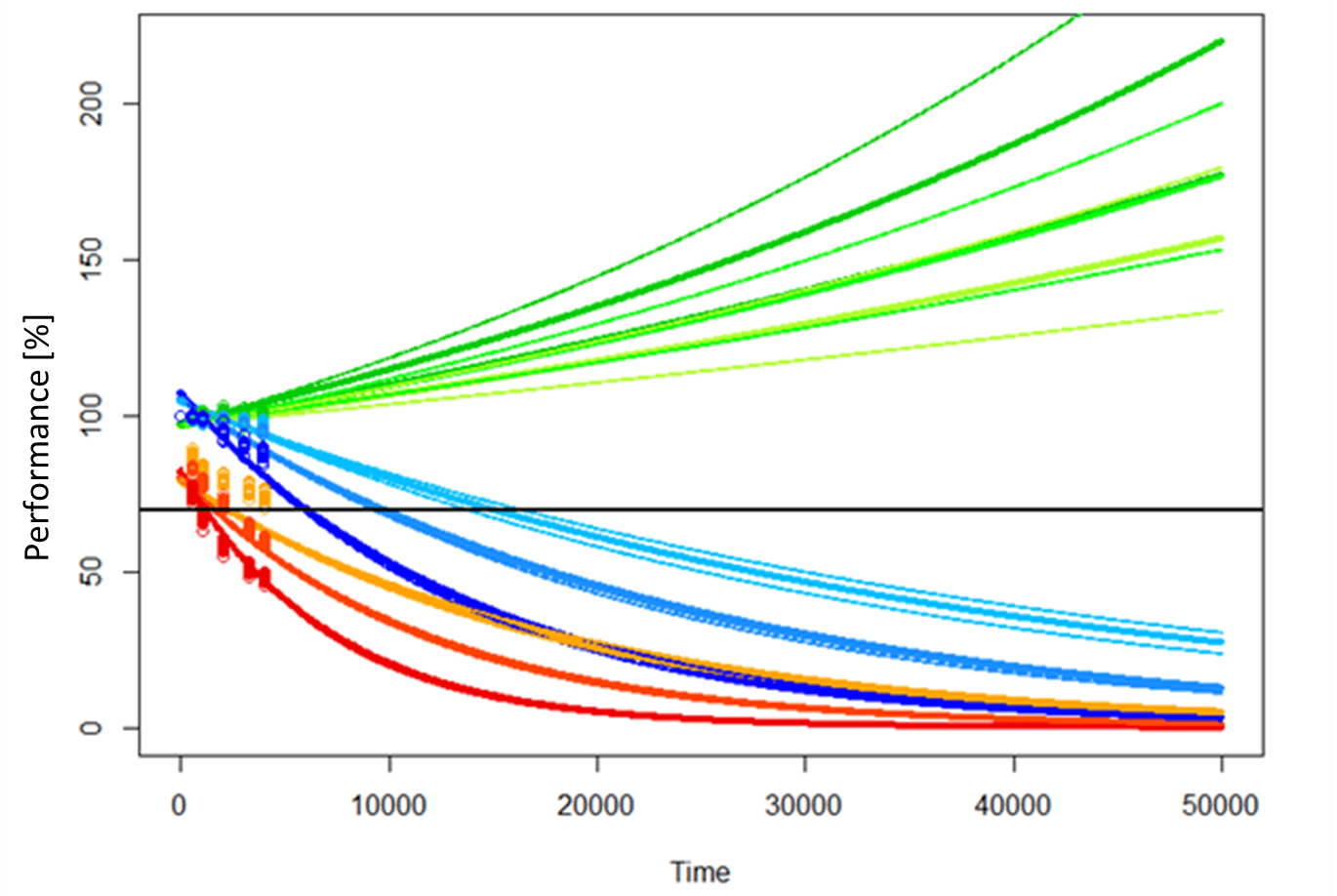

Data-based models for predictive maintenance

Calculation models for the predictive planning and optimization of maintenance measures

Illustration of data-based models Picture: Joanneum Research

Unexpected faults, failures and unplanned downtime lead to a lack of efficiency in systems, machines and components. This can also affect product quality. On the other hand, excessive costs are resulting, if maintenance activities are carried out too frequently or components are replaced too often. Determining optimal maintenance intervals is a complex task that requires not only condition monitoring using suitable sensors, but also expert analysis of the data obtained and the development of reliable predictive models.

What are the benefits of predictive maintenance (PdM)?

PdM provides the basis for customized maintenance, the reduction of downtimes and the avoidance of unplanned breakdowns. Precise maintenance measures reduce wear and tear as well as early failures, thereby extending the service life of systems and components. As maintenance work only takes place when it is needed, personnel and material resources are used more efficiently.

Our offer:

- Analysis and assessment of the suitability of existing data for PdM

- Development of predictive data models for wear, degradation or service life

- Development of optimal maintenance strategies, service intervals or times for component replacement

Research groups

Downloads

Unsere Beteiligten Partner & Fördergeber

Das sagen unsere Kunden

Further products and services

JOANNEUM RESEARCH POLICIES, together with AIT, ZSI and supported by Fraunhofer ISI, form the Mission Facility Austria.

Analyse regional economic effects – differentiated and comprehensive

Ex-ante, interim and ex-post evaluations as well as ex-ante and ex-post impact assessments

Avoiding bias in evaluation policies, processes and practices as a service for research and funding organisations

Take social diversity into account when planning and implementing research and innovation projects

Targeted planning of experiments for more efficient data acquisition

We provide advice and support in the alignment, preparation and formulation of targeted programmes

Tailored evaluation of organizations - from research institutions to universities and technology funding agencies

Estimation of regional effects and impacts based on grid data

Austria's unique collection of regional economic information

Miteinander zukunftsrelevant

Die JOANNEUM RESEARCH ist Innovations- und Technologieanbieter im Bereich der angewandten Forschung. Als Forschungsgesellschaft der Länder und Regionen prägen wir mit unseren Forschungskompetenzen die Entwicklung unserer modernen Gesellschaft und Wirtschaft nachhaltig und menschenzentriert. Als multidisziplinäres Team in flexiblen, innovationsfreundlichen Strukturen leben wir höchste gesellschaftliche und wissenschaftliche Ansprüche.