- About us

- Research expertise

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Research infrastructure

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

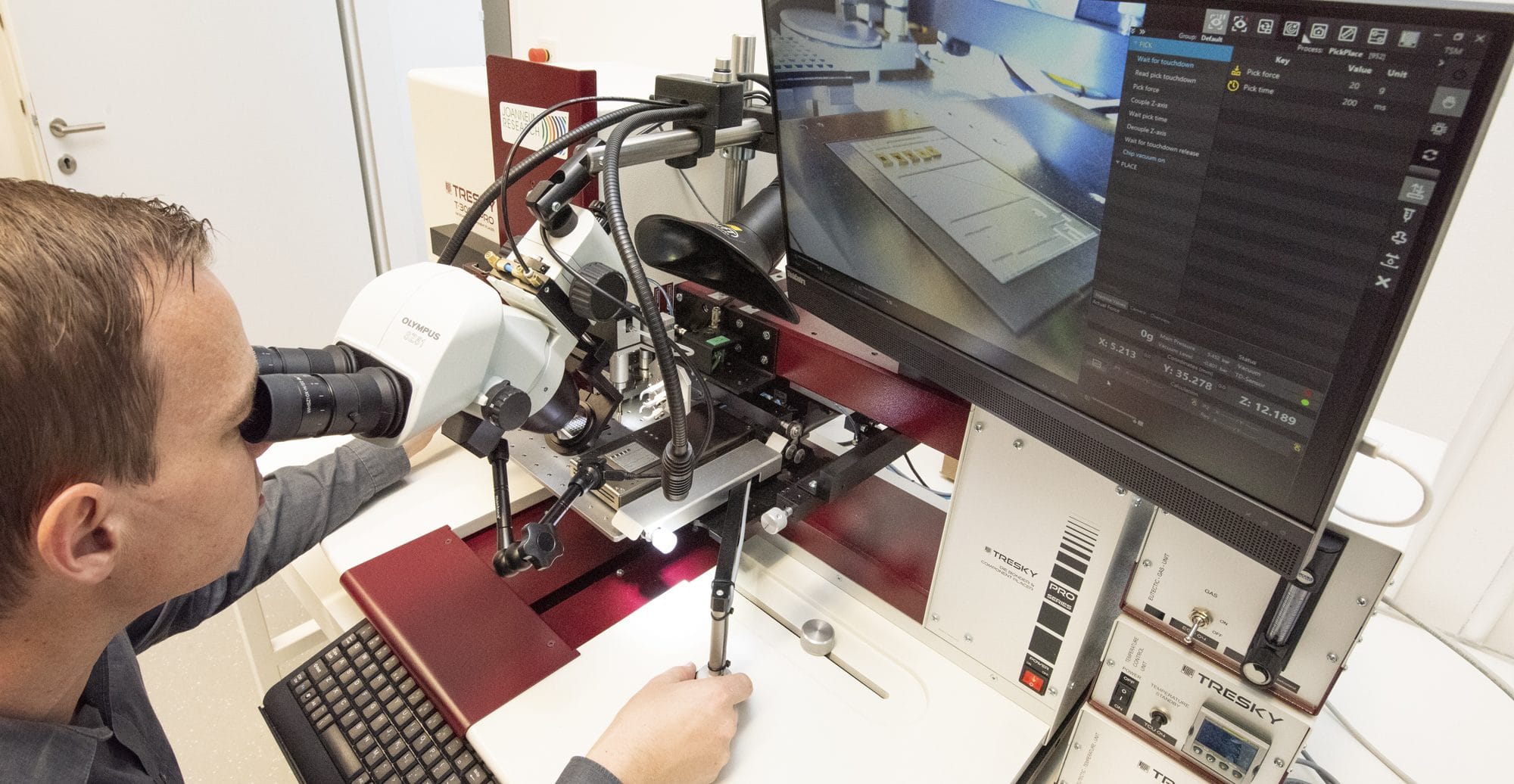

Microassembly Lab

Microassembly Lab for photonic and electronic assemblies

Chip Bonding Plattform, Foto: JOANNEUM RESEARCH/Schwarzl

What does the Microassembly Lab for photonic and electronic assemblies offer?

Design and production of optoelectronic components and devices from micrometre scale to (hybrid) macroscopic assemblies

- Electronic design

EDA software Altium Designer for analogue and digital circuit design, including SPICE simulation; Xilinx and Intel PSG (Altera) design environment for FPGA and CPLD; micro-controller programming (e.g. with ARM KEILTools) - Data and signal analysis

MATLAB, GNU Octave and Simulink/Simscape; algorithm development and system modelling. - Chip bonding platform

This high-precision Tresky platform is capable of placing and bonding electronic components on surfaces with more than 10µ accuracy. The Tresky Chip Bonder features True Vertical Technology™, which guarantees parallelism between chip and substrate. - SMD placement

Neoden 4 pick & place machine - Soldering processes

Inert gas and forming gas reflow soldering up to 450° C (vacuum); vapour phase soldering system (oxygen-free reflow process); universal soldering and repair station (JBC).

Realisation of "Printed Electronics and Optics" through additive processes: Screen printing, inkjet printing/electrostatic inkjet printing (ESJet), aerosol jet printing and atmospheric pressure plasma jet processes.

- Atmospheric pressure plasmajet coating system

Atmospheric pressure plasmajet coating technologies (APPJ) do not require a vacuum chamber and are therefore subject to hardly any size restrictions with regard to the components to be coated. Possible applications include electrical insulation layers or conductor tracks and electrodes, etc. - Inkjet printers

Four modern inkjet printers are available, three PIXDRO LP50 platforms and a Dimatix DMP 2800 printing platform, which enable the use of the most important industrial print head types. - Optomec aerosol jet printers

Our aerosol jet printing process is a non-contact direct structuring process with high resolution (up to 10µm) and also enables the use of non-planar substrates and the creation of 2.5D structures. - ESJET printer

Electrostatic Jet Printing technology is used to apply functional inks in a viscosity range and droplet volume that is currently not available for conventional piezo-based inkjet technologies. - Solenoid valve printers

Compared to inkjet printing, this technology allows the application of larger drop volumes and working in a wider viscosity range with a larger minimum line width and lower possible printing frequency. - Flexographic printing

Highly viscous inks or pastes are applied to the ink application roller via a doctor blade, which then wets the prefabricated cliché with the structures to be transferred. In the roller-based process, the ink is then transferred from the cliché to the substrate to be printed. - Thieme precision screen printing machine

In screen printing, a highly viscous ink or paste is applied to the substrate via a pre-structured screen (stencil) using a doctor blade. Parameters such as squeegee speed, mesh fineness and mesh size of the screen determine the printing result.

Your contact

Location

Das sagen unsere Kunden

Weitere Forschungsinfrastruktur

Modernste Entwicklungsinfrastruktur für ganzheitliches elektronisches und optisches Design inkl. EMV und ESD – offen für Industriepartner.

Unsere Rolle-zu-Rolle Nanoimprint-Lithografie ermöglicht eine kontinuierliche und daher kostengünstige Herstellung von Mikro- und Nanostrukturen auf großflächigen Foliensubstraten für Anwendungen in Hochtechnologiebereichen wie Elektronik, Optoelektronik, Photovoltaik, Sensorik, Mikrofluidik, Folienveredelung und Verpackung, sowie Pharmazeutik und Biowissenschaften.

Aktuellste Infrastruktur zur Lichtmessung und Prototypenfertigung für ganzheitliches optisches und elektronisches Design – offen für Industriepartner.

Unser Labor umfasst Technologien für funktionelle Plasmabeschichtung bei niedrigen Temperaturen von Atmosphärendruck bis Fein- und Hochvakuum.

Drucktechnologien für die Entwicklung von kundenspezifischen 2D-, 2,5D- und 3D-Druckprozessen

Messungen und Analysen von kleinsten Strukturen, Schichten und Bauelementen im Mikro- und Nanomaßstab auf flexiblen Substraten.

We use a specially modified EVG770 Nanoimprint Lithography (NIL) stepper for the large-scale production of micro- and nanostructures in UV imprint resins. Together with special materials and processes, we achieve the highest precision right down to practically seamless transitions between individual structures.

Zertifizierter Reinraum der Klasse 6 für Nanostrukturen und neuartige elektronische Bauelemente und Sensoren

Die hochpräzise maskenlose Laseranlage (MALA) ist für die Herstellung von hochkomplexen und stufenlosen Mikrooptik-Strukturen geeignet.

Das Labor umfasst flexible, schnelle Prototyping-Verfahren zur Herstellung einer Vielzahl von Strukturen in einer breiten Palette von Materialien.

Wir bieten Lasermaterialbearbeitung und langjährige Expertise in Werkstoffkunde.

SHAPING THE FUTURE, TOGETHER

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.