- About us

- Research expertise

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Research infrastructure

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

Step and Repeat UV-nanoimprint lithography

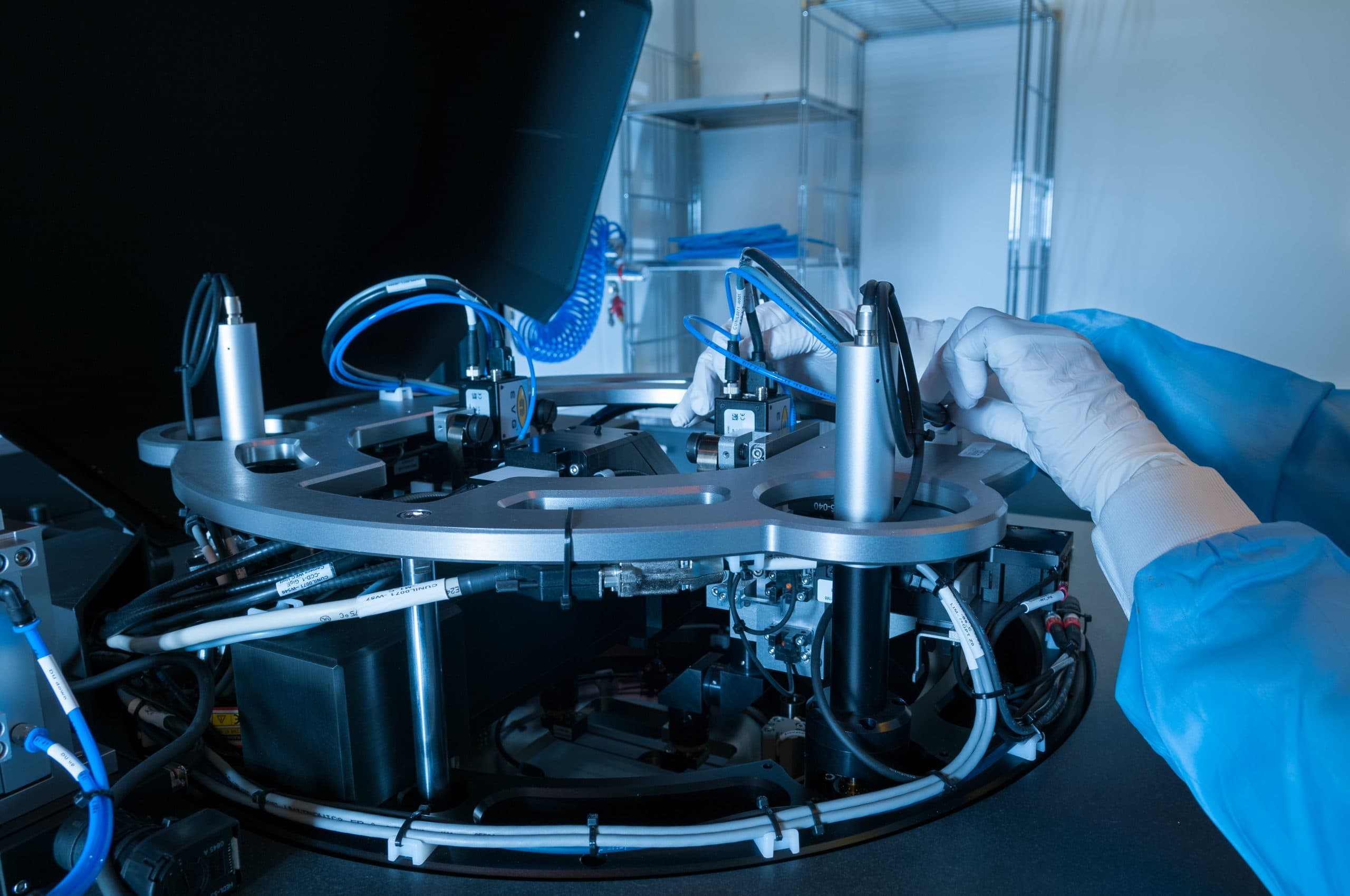

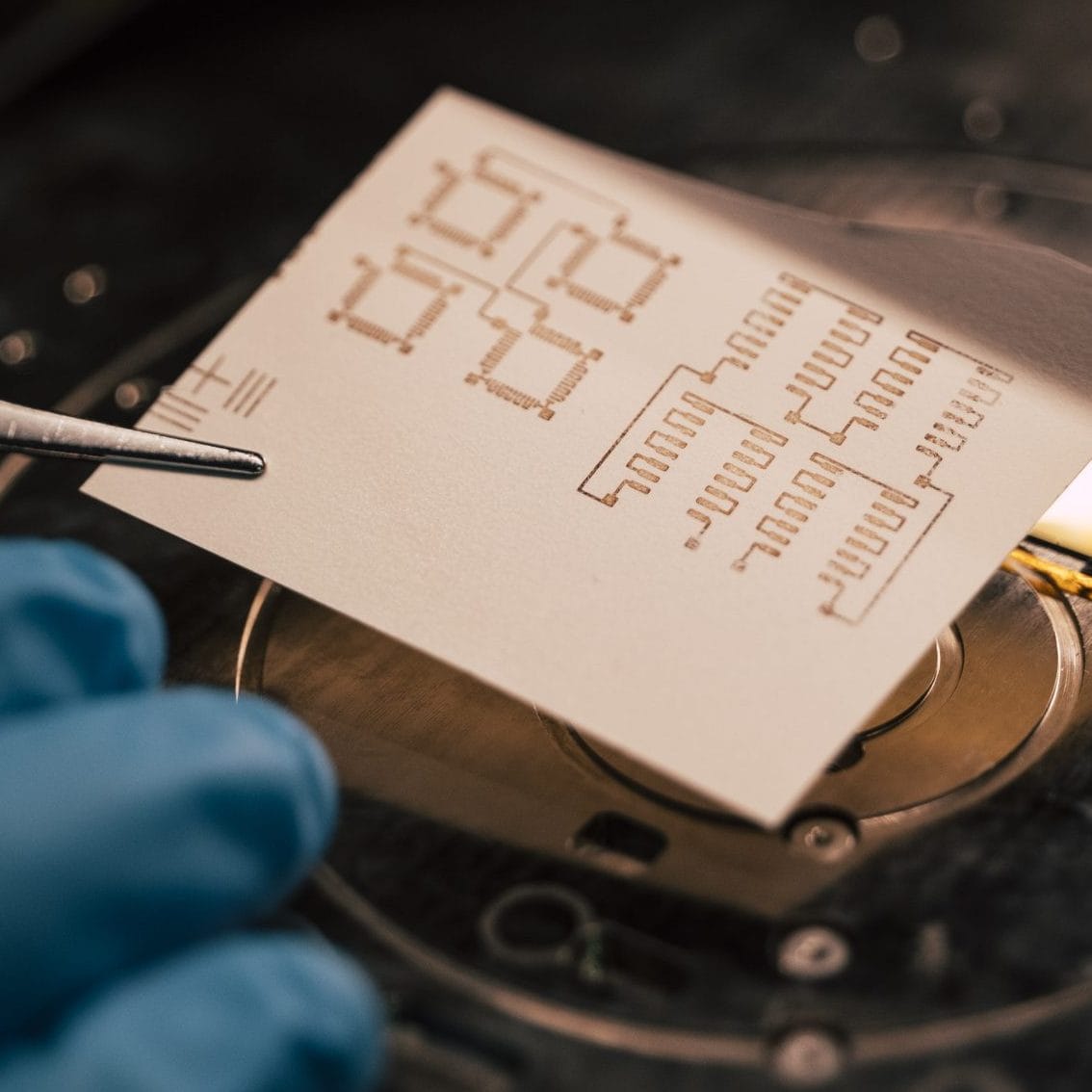

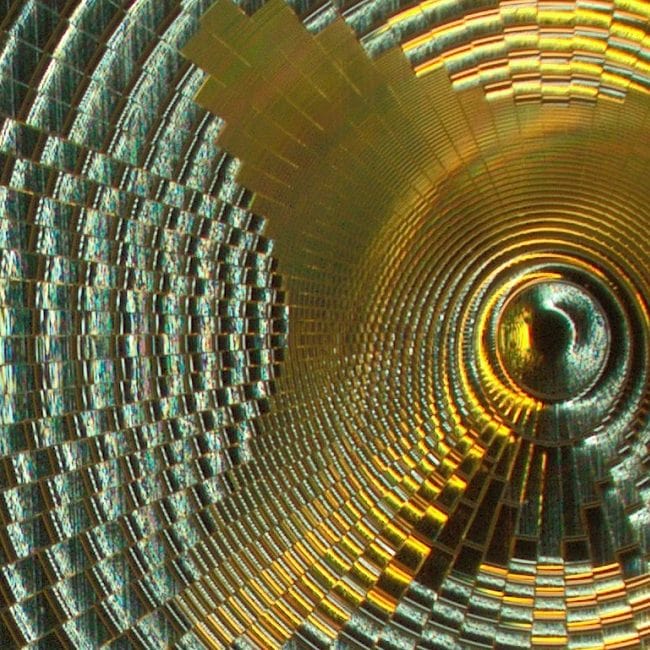

Replication of master structures almost seamlessly onto large surfaces (380 x 700 mm²) using a step&repeat UV-NIL process

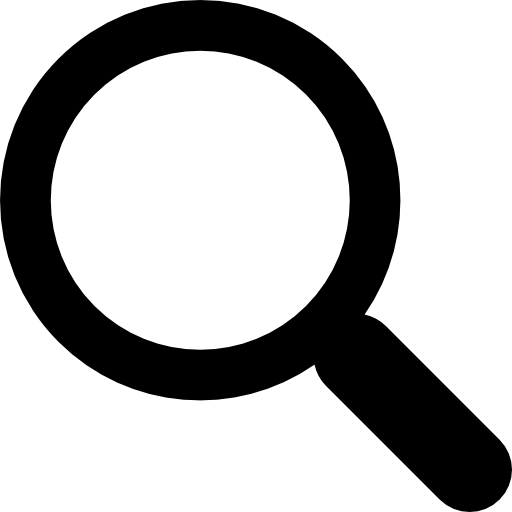

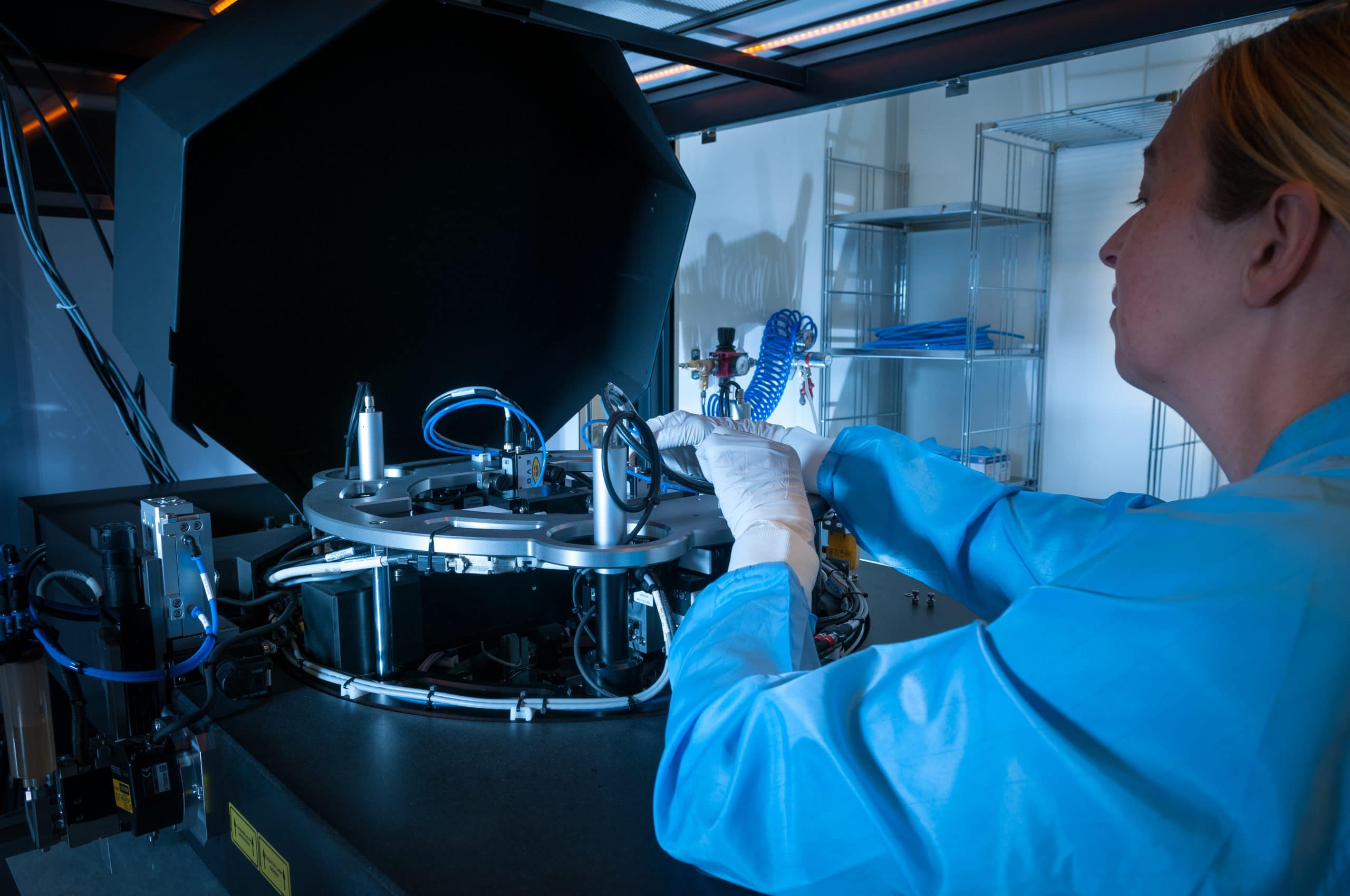

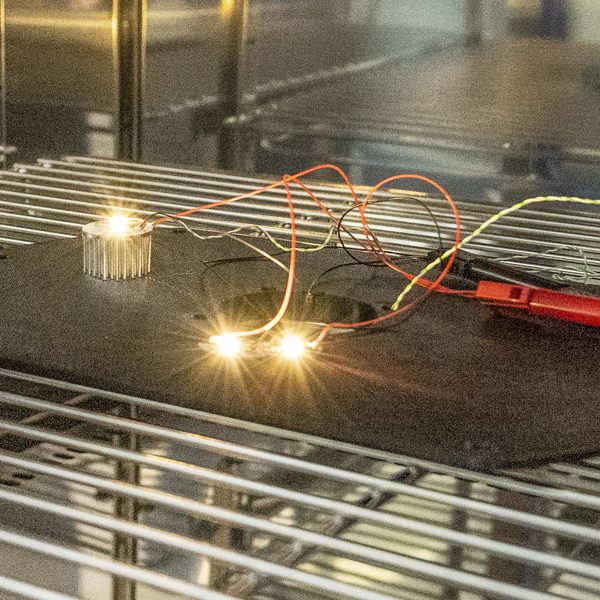

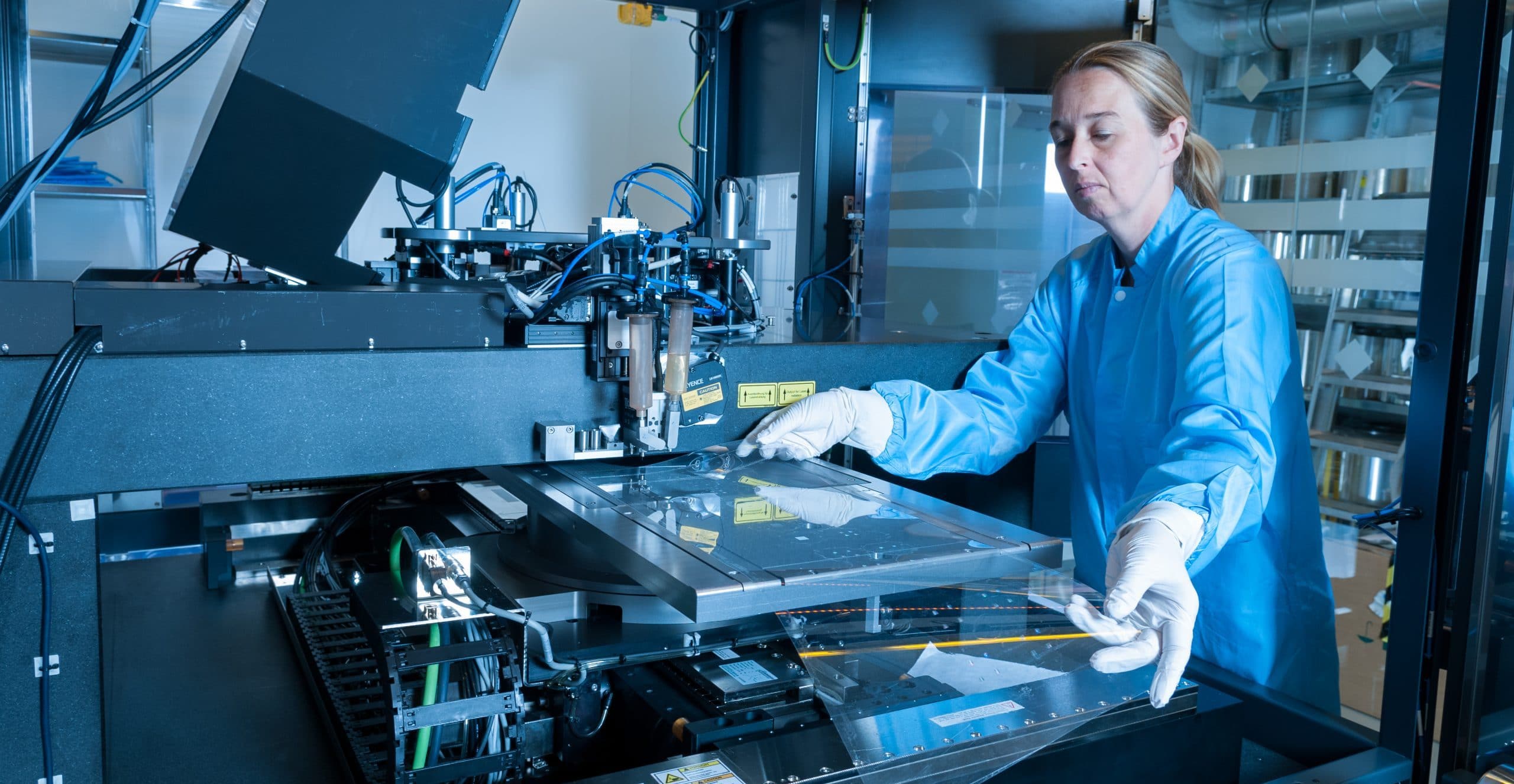

Step and Repeat-Anlage Foto: JOANNEUM RESEARCH/Stadler

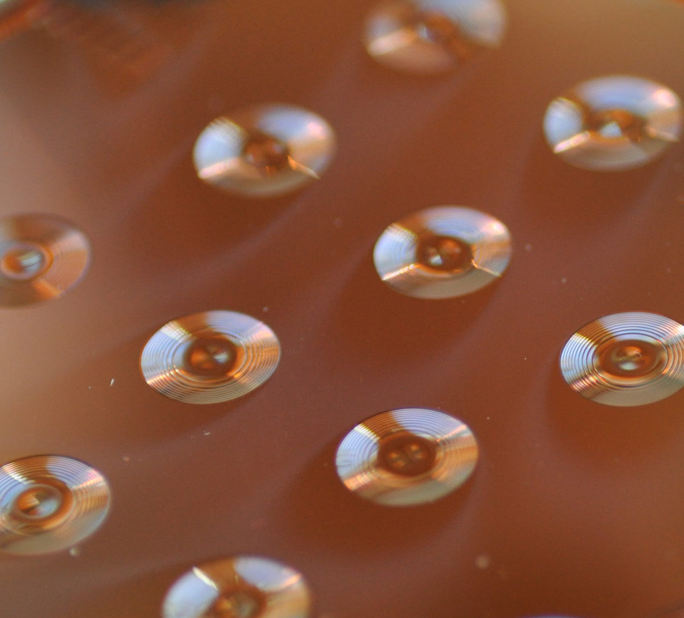

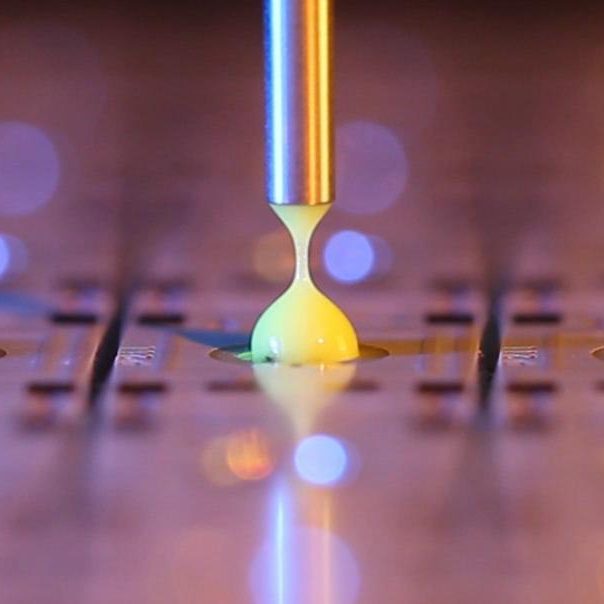

Using the Step&Repeat UV-NIL process, we replicate small master structures almost seamlessly onto large surfaces (380 x 700 mm²). We use this process for customised replications of micro and nanostructures or for the production of tools for our R2R pilot line.

Our offer

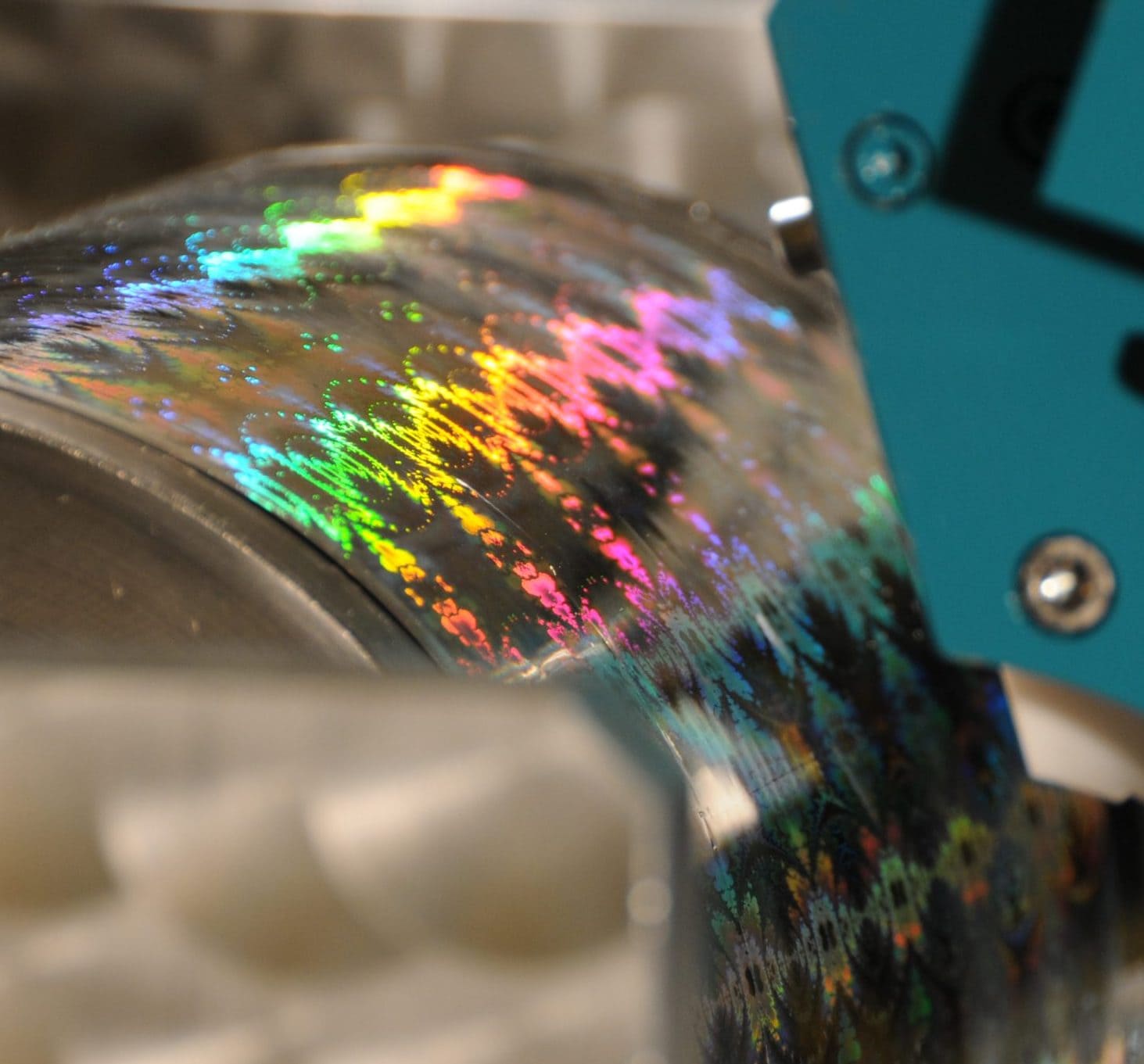

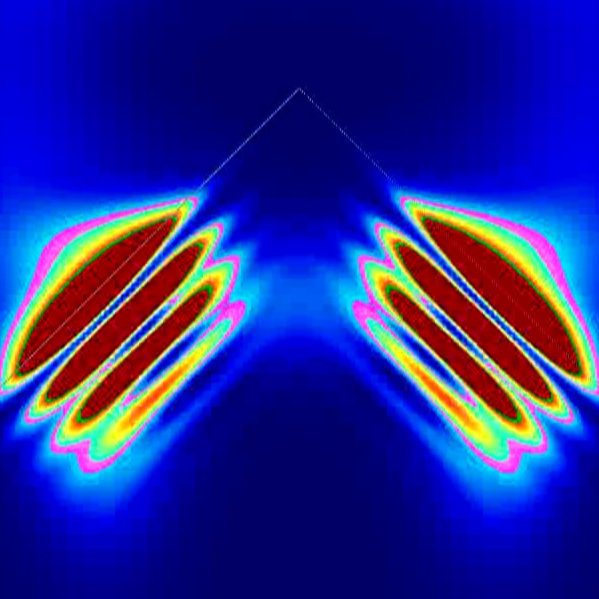

We offer our customers and partners research pilot lines for the development and implementation of new product ideas and manufacturing processes, from the idea to the prototype. The pilot line for roll-based micro- and nanostructuring at the MATERIALS Institute includes simulation, design and material development (coatings, imprint resins) and offers large-area structuring and structure replication from mastering to high-throughput production. The EVG770 NILStepper completes this pilot line with regard to the production of flexible working stamps for roller-based processes.

Advantages of nanoimprint lithography

Compared to other lithographic processes, nanoimprint lithography is a cost-effective structuring technology and ideal for use in high-volume manufacturing processes. The time and cost associated with the production of working stamps for industrial-scale, roll-based embossing is still significant. The development of Step+Repeat technology for large-area foil substrates enables us to bridge the gap between small-format masters and large-area working stamps.

Among other things, this brings significantly greater process flexibility and a further reduction in process costs in the area of nanoimprint technology. The adaptation of the EVG770 system together with EV Group primarily involved expanding the sample pick-up from wafer geometries to large-area film substrates.

Using a step+repeat technology based on UV embossing, flexible, polymer-based working stamps are created for use in roll-to-roll embossing processes. The approach combines the very high positioning accuracy of semiconductor technology with film-based high-throughput methods and provides a cost-effective and industrially suitable alternative to the direct use of conventional time-consuming nanostructuring processes.

Research groups

Downloads

Unsere Beteiligten Partner & Fördergeber

Das sagen unsere Kunden

Other products and services

Environmental, bioanalytical and diagnostic sensor technology combined with smart microfluidic lab-on-a-chip and organ-on-a-chip systems

Cost-effective solutions by extending the functions of classic LED-based lighting systems in the areas of Visible Light Communication, Visible Light Positioning and Visible Light Sensing

R2R-UV-NIL pilot line for the continuous and cost-effective production of micro- and nanostructures on flexible large-area film substrates

Gesamtkonzepte für Design, Simulation, Optimierung und Prototyping von optischen Komponenten für maßgeschneiderte Lichtlösungen

High-resolution 3D structuring using two-photon lithography, as well as 2D and continuous 2.5D structuring using maskless grayscale laser lithography and electron beam lithography

Messungen und Analyse von kleinsten Strukturen, Schichten und Bauelementen im Mikro- und Nanometermaßstab

Neuartige Technologie zur Verlängerung der Topfzeit von Silikonen auf mehrere Monate, ohne die Materialeigenschaften zu verändern

Complete solutions from optical simulation, mastering and prototyping to the transition to high volume, cost effective production of optical structures and components

Wiederverwendbare Materialien, Komponenten bzw. Verbundstoffen und deren Anwendungen, wie z.B. selbst entwickelte Lacke für die UV-Imprint-Lithografie (NILcure®)

Printable sensor inks and sensors with piezoelectric, pyroelectric and magnetoelectric features

Additive manufacturing thanks to new design and simulation tools, new materials and the realisation of special topological structures

SHAPING THE FUTURE, TOGETHER

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.