- About us

- Research fields

- DIGITAL – Institut für Digitale Technologien

- MATERIALS – Institut für Sensorik, Photonik und Fertigungstechnologien

- ROBOTICS – Institut für Robotik und Flexible Produktion

- COREMED – Zentrum für Regenerative Medizin und Präzisionsmedizin

- HEALTH – Institut für Biomedizinische Forschung und Technologien

- LIFE – Institut für Klima, Energiesysteme und Gesellschaft

- POLICIES – Institut für Wirtschafts-, Sozial und Innovationsforschung

- Business areas

- Products & services

- Research infrastructure

- Beteiligungen

- Career

- Aktuelles

- Publications

- Kontakt zu uns

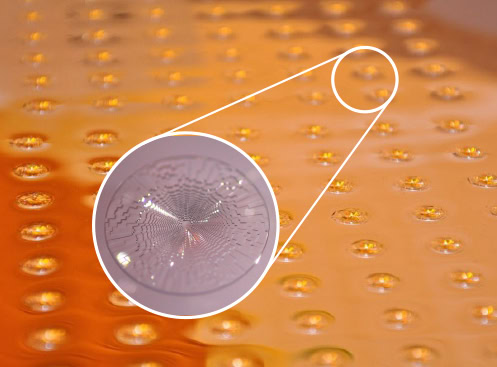

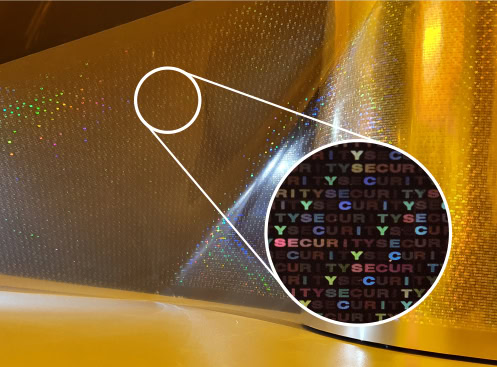

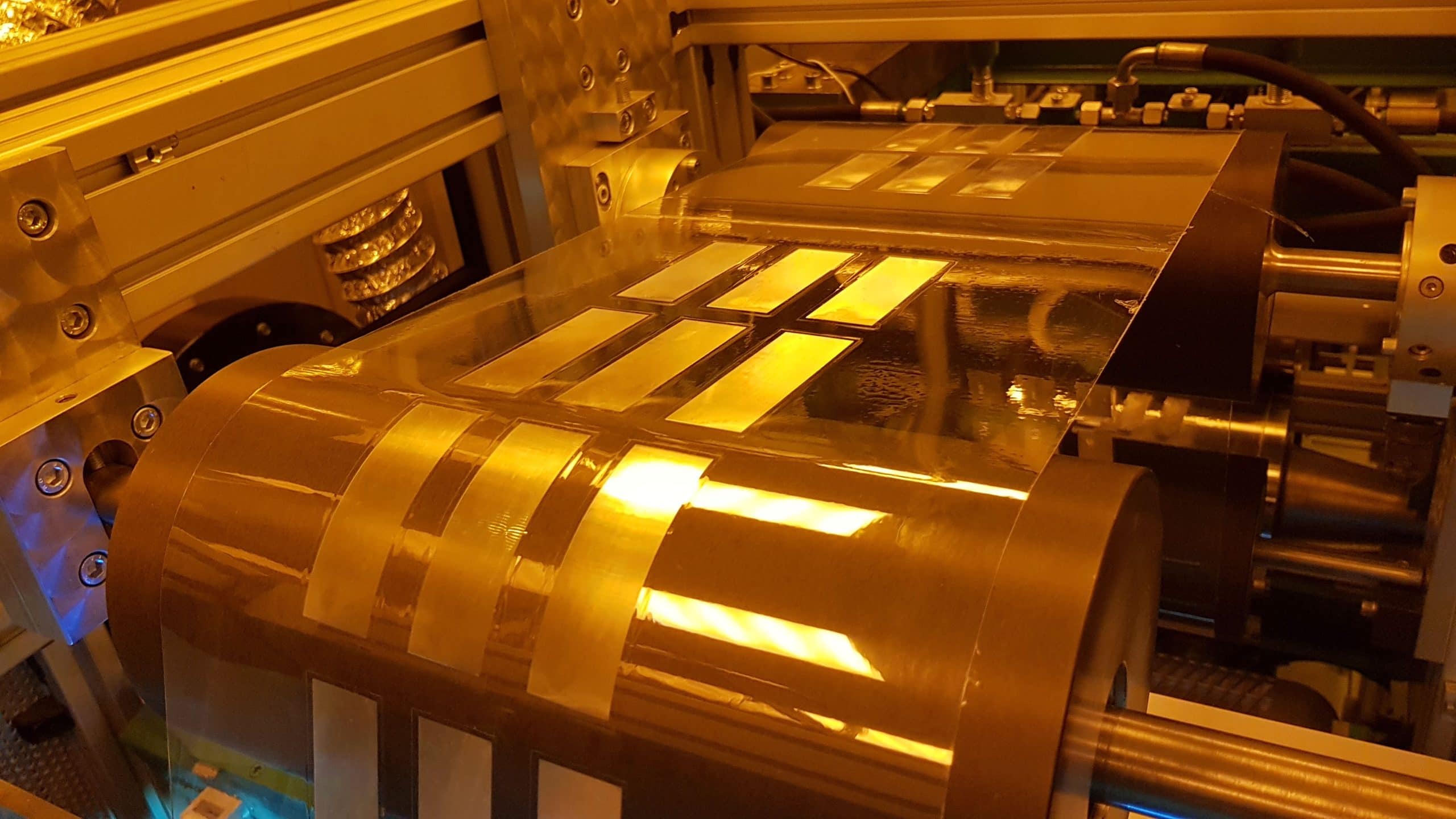

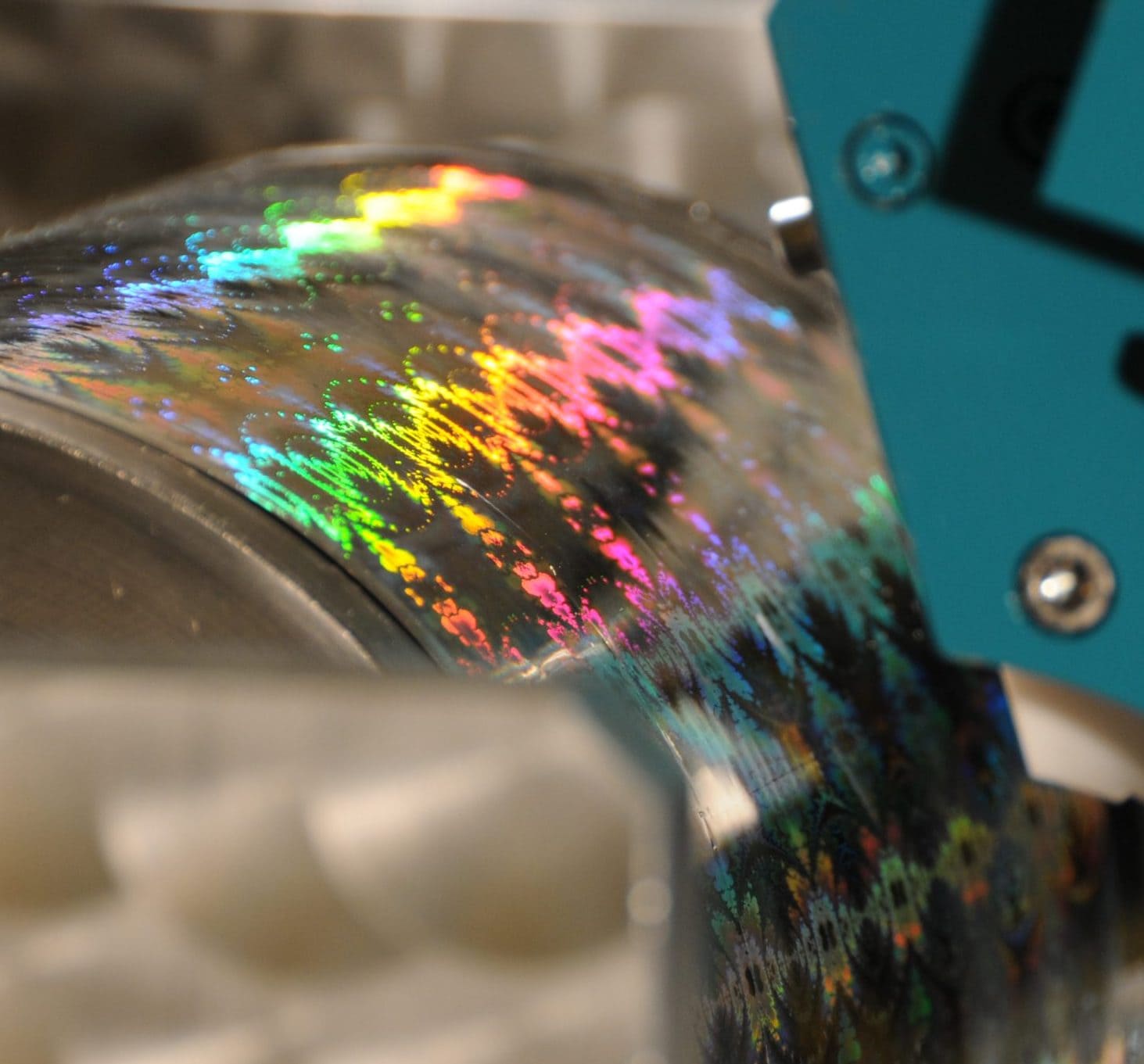

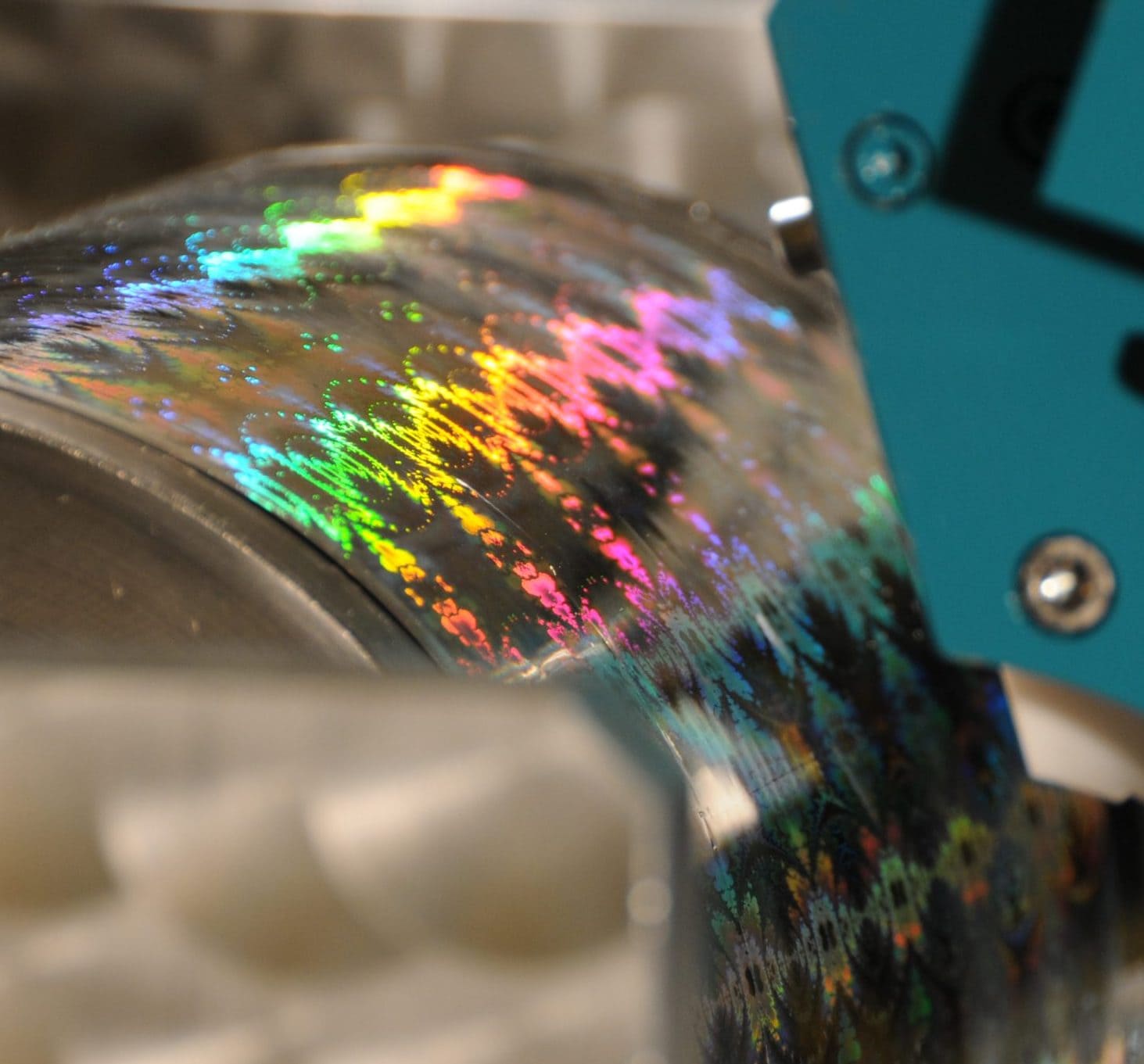

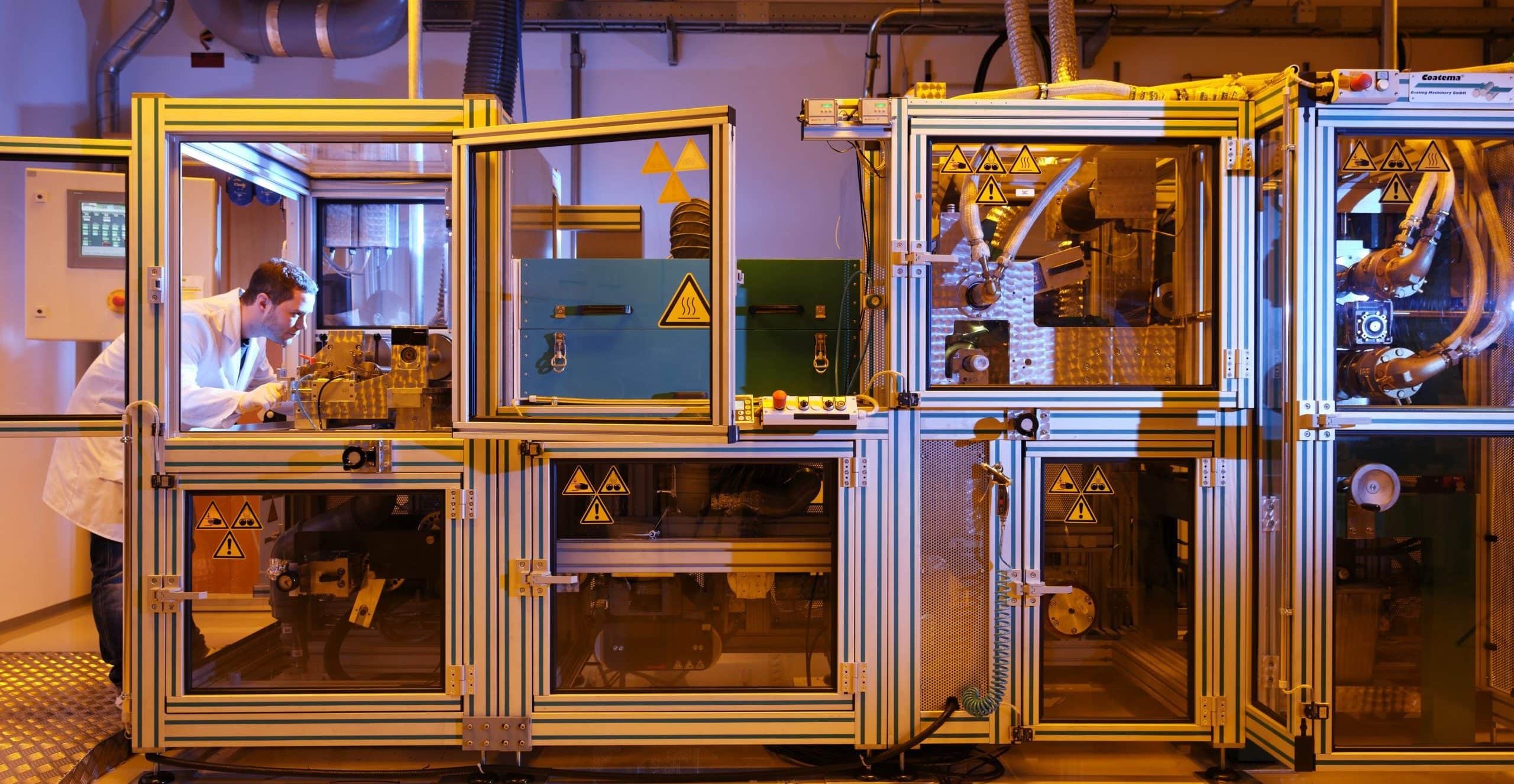

R2R pilot line for micro- and nanostructuring

R2R-UV-NIL pilot line for the continuous and cost-effective production of micro- and nanostructures on flexible large-area film substrates

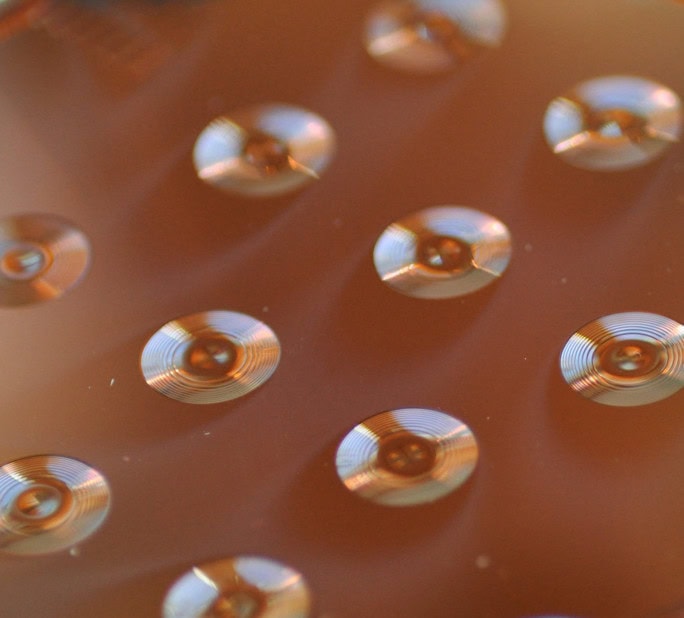

Rolle-zu-Rolle-Anlage (credit: JOANNEUM RESEARCH)

Roll-to-roll nanoimprint lithography

Our R2R-UV-NIL pilot line enables the continuous and cost-effective production of micro and nanostructures on flexible large-area film substrates for applications in lighting, photovoltaics, AR/VR, AR/VR, microfluidics, diagnostics, security, film finishing and packaging, the pharmaceutical industry and life sciences.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

What can we achieve with our R2R system?

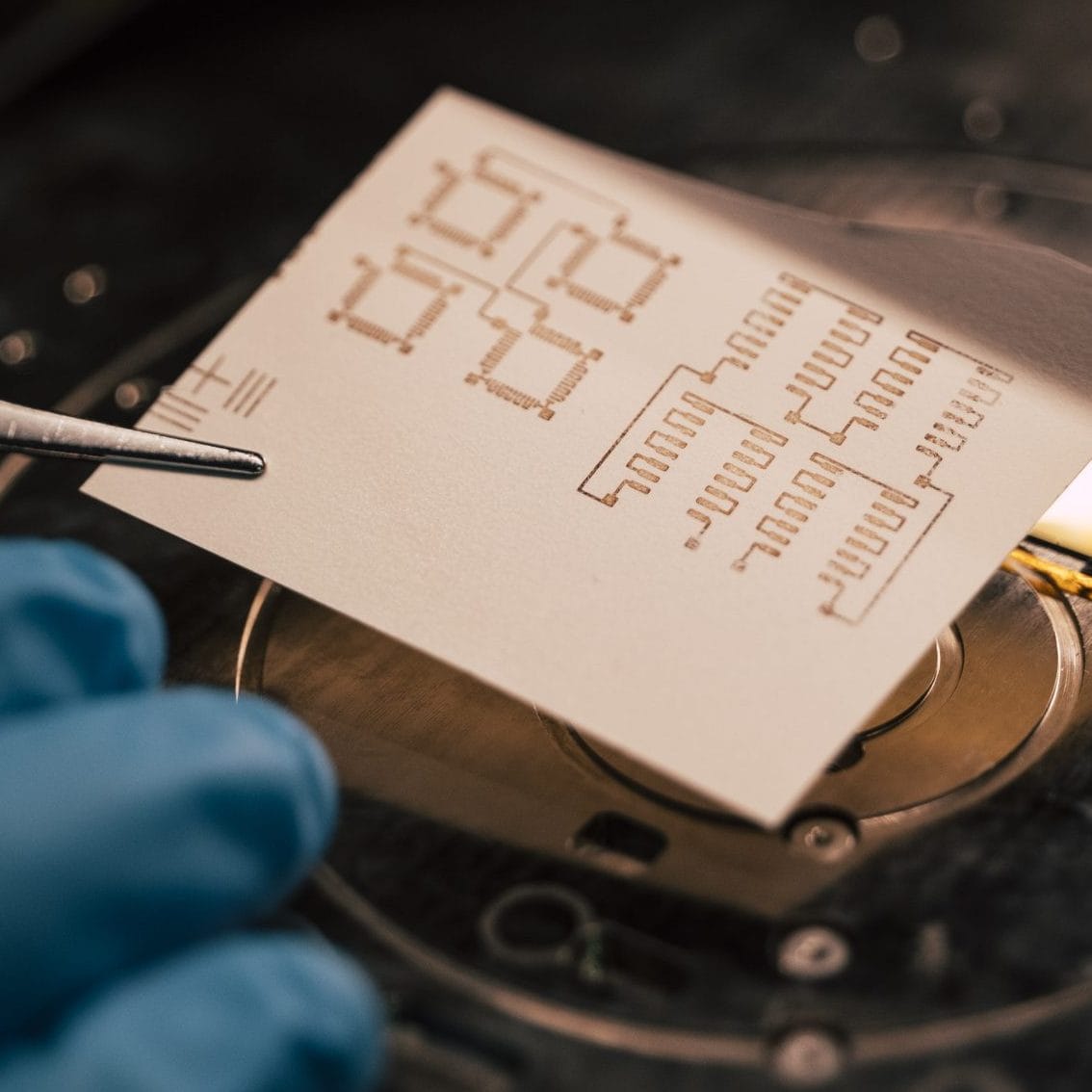

- sustainable production of high-resolution conductive structural elements for organic electronics (fine conductor tracks, nanoscale electrodes for organic transistors)

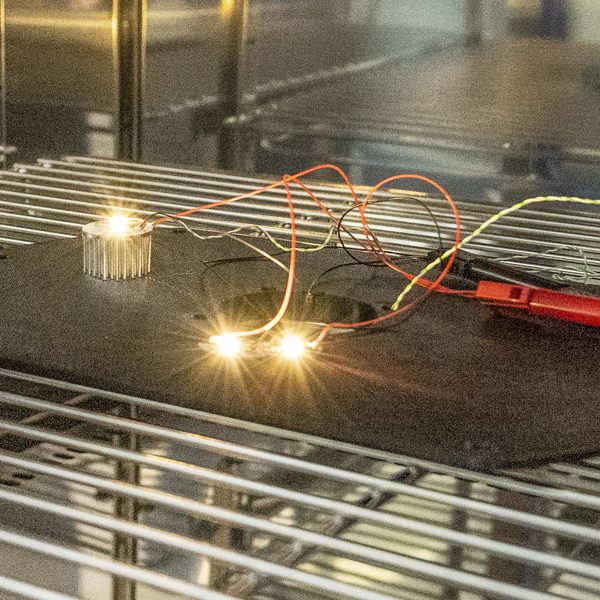

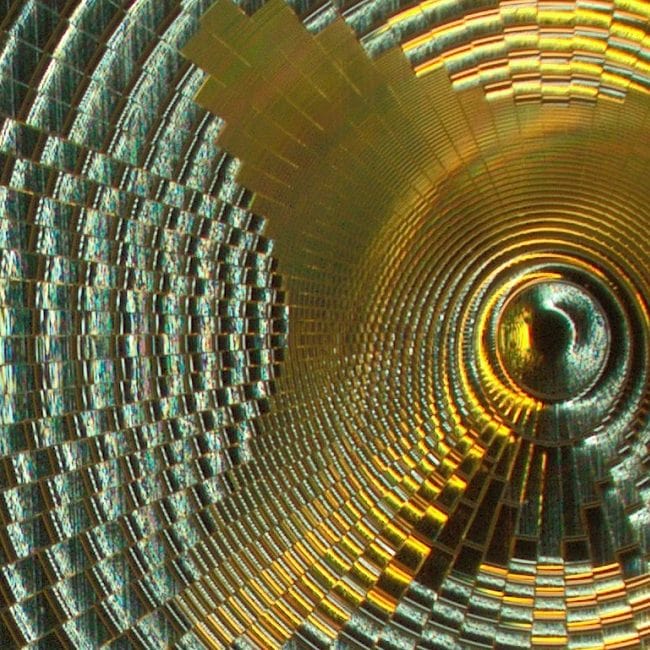

- precise optical creation of 2.5D structures for the light management in flexible films (coupling and outcoupling, light guiding) for applications in photonics

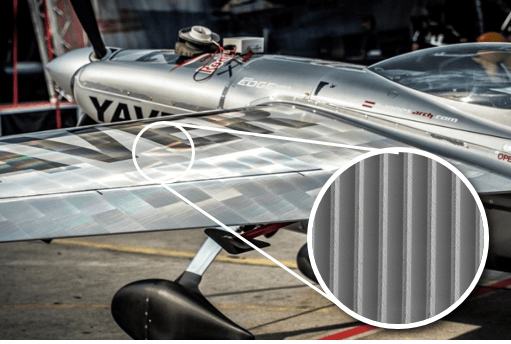

- large-scale realisation of structured bionic surfaces and complex nanopatterns, which allow the artificial imitation of biological characteristics (shark skin, lotus effectgecko effect, structural colors)

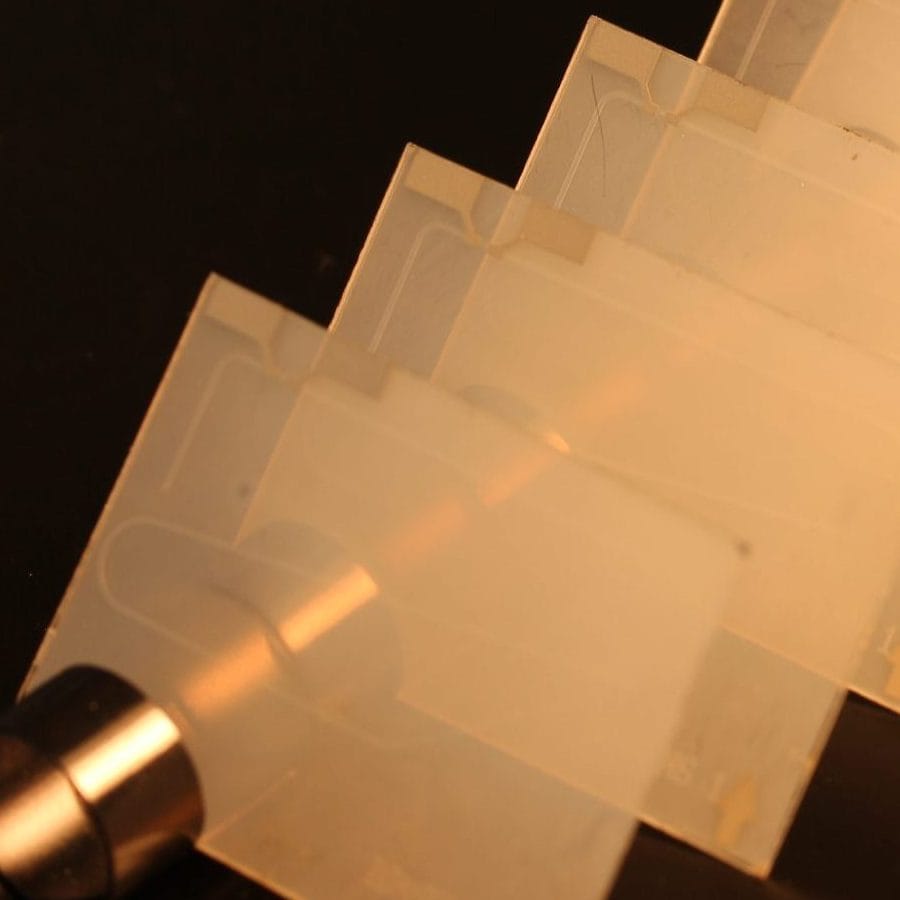

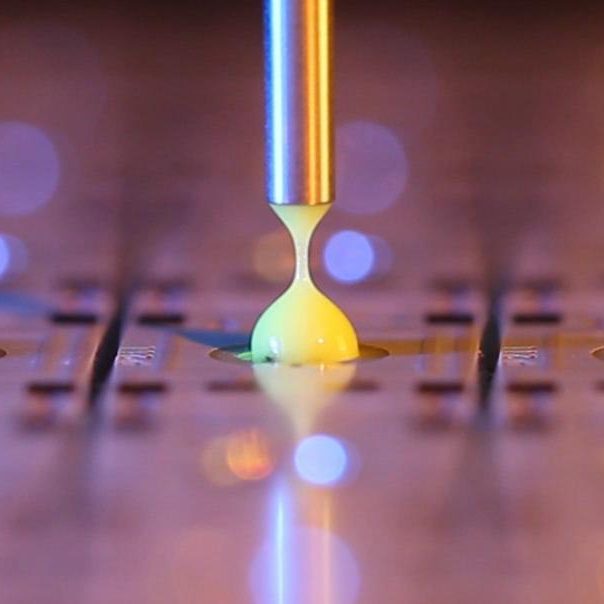

- cost-effective production of complex microfluidic elements on foil for bioanalytic lab-on-foil systems

- continuous production of optimized high-tech film surfaces for packaging, decoration, safety and labeling, which display improved optical, mechanical and chemical behavior due to their micro and nanostructural properties

Discover illustrative application examples of our solutions in short videos.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Research groups

Downloads

Unsere Beteiligten Partner & Fördergeber

Das sagen unsere Kunden

Other products and services

Environmental, bioanalytical and diagnostic sensor technology combined with smart microfluidic lab-on-a-chip and organ-on-a-chip systems

Cost-effective solutions by extending the functions of classic LED-based lighting systems in the areas of Visible Light Communication, Visible Light Positioning and Visible Light Sensing

High-resolution 3D structuring using two-photon lithography, as well as 2D and continuous 2.5D structuring using maskless grayscale laser lithography and electron beam lithography

Replication of master structures almost seamlessly onto large surfaces (380 x 700 mm²) using a step&repeat UV-NIL process

Measurement and analysis of the smallest structures, layers and components on a micro- and nanometre scale

Complete solutions from optical simulation, mastering and prototyping to the transition to high volume, cost effective production of optical structures and components

Reusable materials, components and compounds and their applications, e,g, coatings developed in-house for UV imprint lithography (NILcure®)

Compact solutions for the Future of Quantum and Optical Technologies

Printable sensor inks and sensors with piezoelectric, pyroelectric and magnetoelectric features

Additive manufacturing thanks to new design and simulation tools, new materials and the realisation of special topological structures

SHAPING THE FUTURE, TOGETHER

JOANNEUM RESEARCH provides innovation and technology services in the field of applied research. As a research company working on behalf of various federal provinces and regions in Austria, our expertise shapes the development of our modern society and economy – sustainably, and always with a focus on people. As a multidisciplinary team working in a flexible set-up that fosters innovation, we always live up to the highest social and scientific standards.